1.Engineered for Speed, Keeping Your Line Moving

•Lightning-Fast Curing: Bonds in seconds, perfectly syncing with high-speed lines running dozens or even hundreds of cartons per minute, directly boosting your output capacity.

•Smooth, Reliable Operation: Formulated for a wider operating temperature range and excellent heat stability with minimal charring in the equipment. This translates to less downtime for cleaning and maintenance, keeping your production flowing consistently.

2.Built for Strength, Protecting Your Shipment

•Powerful Bonding Strength: Offers strong penetration and adhesion to corrugated board, creating a more rigid, deformation-resistant carton that better withstands stacking pressure and transport shocks.

•Broad Substrate Compatibility: Provides a reliable bond on various board types, including those with coatings, laminations, or high-quality prints, effectively eliminating weak or false bonds.

3.Cost-Effective & Sustainable

•Lower Total Cost of Ownership: While adhesive cost per unit may be higher, hot melt sealing often has a lower total cost per carton compared to traditional tapes or straps. Crucially, it delivers superior bonding with less adhesive, helping you control material usage precisely.

•100% Recyclable & Eco-Friendly: The adhesive is non-toxic and odorless. A key advantage is that sealed cartons can be pulped for recycling without complex separation steps needed for tape removal, aligning with sustainability goals.

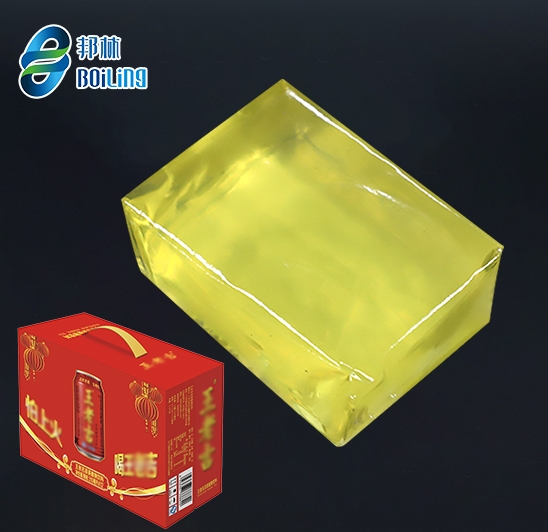

4.Enhanced Aesthetics & Security

•Clean, Invisible Bond: The bond is formed between the flaps, preserving your package’s graphics for maximum visual impact. Proper application ensures no stringing or dripping for a neat finish.

•Built-in Tamper Evidence: Once sealed,Forcefully opening the carton will tear the board fibers, leaving visible evidence and deterring unauthorized access.