5 Common Bubble Mailer Sealing Failures and How to Prevent Them

Bubble mailers have become a go-to for e-commerce sellers and shippers everywhere. They’re lightweight, protective, and cost-effective. But nothing kills the vibe faster than a package arriving with the seal popped open. Items spill out. Customers get frustrated. Returns pile up, and your reputation takes a hit.

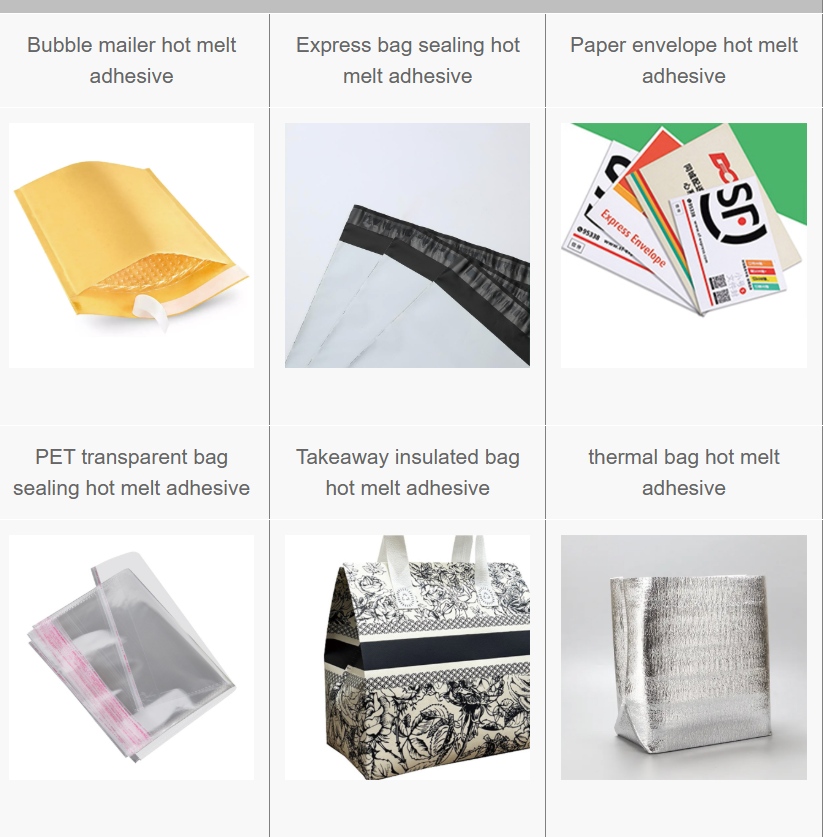

Sealing failures happen more often than you’d think. Rough handling in transit, temperature swings, or just a glue that doesn’t hold up – these can turn a reliable mailer into a headache. The good news? Most issues tie back to the bubble mailer hot melt adhesive. Pick the right one, and apply it properly. Suddenly, those problems fade away.

In this post, we’ll break down five typical sealing failures you see with bubble mailers. We’ll explain why they happen and, more importantly, how to stop them in their tracks.

1. Pop-Opens During Transit

Picture this: A stack of bubble mailers loaded onto a truck. They bounce around for days. By the time they reach the customer, the flap has popped open. Contents are damaged or gone.

This is one of the most common complaints. It often stems from weak initial tack or poor shear strength in the adhesive. The glue grabs at first but can’t handle the constant flex and jolts.

Why It Happens

-

Not enough compression when sealing.

-

Glue sets too fast before full contact.

-

Adhesive lacks the grip needed for PE films and bubble layers.

How to Prevent It

Use a bubble mailer hot melt adhesive with fast tack and quick setting. It bonds instantly on high-speed lines. Add strong permanent hold. Many operations see pop-opens drop by 70-80% after switching to specialized formulas. Apply steady pressure during sealing – even a second or two makes a difference.

2. Seals Failing in Extreme Temperatures

Ships go from hot warehouses to freezing trucks. Or vice versa. Temperature changes stress the seal big time.

In cold weather, some glues turn brittle and crack. In heat, they soften and ooze. Either way, the mailer opens up.

Real example: During holiday peaks, one online retailer in the Northeast dealt with a surge in opened packages after cold snaps. Seals just gave way.

Why It Happens

-

Narrow temperature resistance in the glue.

-

Poor flexibility at low temps or stability at high ones.

How to Prevent It

Go for adhesives with wide temperature tolerance. They stay stable in hot and cold conditions. Look for ones that resist aging and UV too. That keeps bonds intact through storage and shipping swings.

3. Weak Adhesion to Bubble Materials or Printed Films

Bubble mailers have that cushy interior lining and slick PE outer layer. Sometimes recycled or printed. Glue needs to wet out and grip both surfaces evenly.

If it doesn’t spread well, you get spotty bonds. Flaps peel easy, especially with tamper attempts or rough sorting machines.

Why It Happens

-

Glue doesn’t flow properly on tricky substrates.

-

Surface contamination or incompatible formulas.

How to Prevent It

Choose a bubble mailer hot melt adhesive built for excellent compatibility with PE/PP films and bubble interiors. It spreads fast and bonds deep. Clean surfaces before application. Test on your exact materials – printed, recycled, whatever you run.

4. Tamper-Evident Seals That Aren’t So Evident

Customers want proof their package hasn’t been messed with. A good seal should show clear damage if someone tries to open it.

But cheap glues let flaps lift clean. No tears, no evidence. That erodes trust fast.

Why It Happens

-

Reversible or low-cohesion adhesives.

-

Not enough permanent bonding strength.

How to Prevent It

Opt for permanent sealing types. Once closed, any opening leaves visible tears or stretching. Pair that with strong, tamper-evident properties. It’s a small detail that boosts customer confidence huge.

5. Slow Production or Inconsistent Seals on Fast Lines

High-volume shippers crank out hundreds of mailers an hour. Glue that strings, clogs nozzles, or sets uneven slows everything down.

Inconsistent bonds mean rework. Or worse, failures slip through.

Why It Happens

-

Wrong viscosity or application temp.

-

Glue not suited for automated equipment.

How to Prevent It

Select low-viscosity options around 1500 cps at 180°C. They flow smooth at 150-180°C. No stringing, quick grab. Run trials to dial in settings.

Here’s a quick comparison of common issues and fixes:

| Failure Type | Common Cause | Key Prevention with Quality Adhesive |

|---|---|---|

| Pop-Opens | Weak tack, poor compression | Fast tack & strong shear hold |

| Temp-Related Failures | Narrow resistance range | Wide hot/cold stability |

| Poor Substrate Grip | Bad wettability on PE/bubble | Excellent film & lining compatibility |

| Lack of Tamper Evidence | Reversible bonding | Permanent, destructive-open seal |

| Line Inefficiencies | Stringing or uneven flow | Proper viscosity & quick setting |

Practical Tips for Better Bubble Mailer Sealing

A few shop-floor habits go a long way.

-

Keep application temps steady at 150-180°C. Let machines warm up fully.

-

Store glue blocks dry and cool.

-

Apply even beads – not too much, not too little.

-

Compress flaps firmly right after gluing.

-

Run spot checks on sealed mailers daily.

These steps, combined with the right bubble mailer hot melt adhesive, cut failures sharp.

About Banglin: Your Go-To Hot-Melt Adhesive Supplier

Banglin – that’s Hangzhou Boiling Adhesive Technology Co., Ltd. – has been turning out reliable hot melt adhesives since 2005. We’re tucked in Hangzhou, China, and we’ve earned our stripes as a national high-tech outfit.

Our R&D lab spans over 500 square meters. It’s packed with top-notch gear, like imported rheometers. Seasoned engineers – some with 30 years in the game, plus PhD guidance – cook up innovative formulas. We’ve got patents to show for it.

We shine in pressure-sensitive hot melts, including our solid bubble mailer hot melt adhesive. It’s tailored for tough packaging jobs, delivering permanent bonds that stand up to real-world abuse. We serve thousands of customers, from logistics to labels. Full ODM/OEM support, steady supply, and hands-on help to trim costs and boost results.

Conclusion

Bubble mailer sealing failures don’t have to be part of your routine. From pop-opens to temp troubles, most stem from mismatched adhesives. Switch to a dedicated bubble mailer hot melt adhesive – one with fast tack, wide temp resistance, strong grip on films and bubbles, tamper evidence, and smooth application. You’ll see fewer returns, happier customers, and smoother shipping.

It’s a straightforward fix that protects your bottom line. Curious about upgrading your seals? Drop a line – let’s talk specifics for your setup.

FAQs About Bubble Mailer Hot Melt Adhesive

Q: Why do bubble mailers pop open in transit?

A: Often from weak initial tack or not enough hold against bumps. A good bubble mailer hot melt adhesive grabs fast and stays tough for reliable seals.

Q: How can I stop seals from failing in cold or hot weather?

A: Pick a bubble mailer hot melt adhesive with wide temperature resistance. It keeps bonds stable through extremes, no cracking or softening.

Q: Does bubble mailer hot melt adhesive work on printed or recycled mailers?

A: Yes, quality ones offer excellent spread and grip on PE/PP films and bubble linings – even printed or reclaimed materials.

Q: What makes a seal tamper-evident with bubble mailer hot melt adhesive?

A: Permanent bonding formulas. Once sealed, opening causes visible damage, so tampering shows clear.

Q: What’s the ideal application temp for bubble mailer hot melt adhesive?

A: Between 150-180°C. That ensures smooth flow, quick setting, and strong bonds on fast lines.