5 Common Lipstick Tube Assembly Failures and How the Right Hot Melt Prevents Them

Ever picked up a lipstick and felt that satisfying click as it twists up? That’s the magic of solid assembly work. But when things go wrong in production, it can turn a premium product into a headache for manufacturers and users alike. In the cosmetics world, lipstick tubes are more than just packaging—they’re the first touchpoint for your brand. Messy bonds or shaky parts? That spells trouble. This post dives into five typical slip-ups during lipstick tube assembly and shows how picking the right hot melt adhesive can fix them for good. We’re talking real-world fixes that keep lines running smooth and products lasting longer.

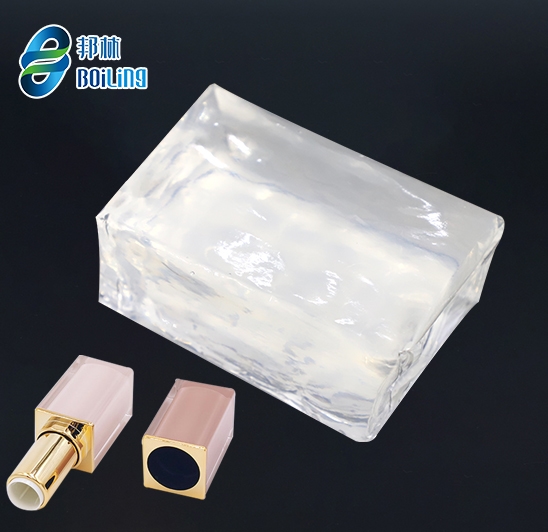

Why Lipstick Tube Assembly Matters

Let’s get real: lipstick tubes aren’t simple. You’ve got metal casings hugging plastic internals, rotating bits that need to spin without a hitch, and everything has to look flawless. A weak glue job here means returns, bad reviews, and lost bucks. Manufacturers deal with high-speed lines where every second counts. The right adhesive isn’t just sticky—it’s got to handle heat, cold, and daily twists without breaking a sweat. Stick around as we break down the fails and the saves.

Failure 1: Loose Rotating Mechanisms

Picture this: a batch of lipsticks hits the shelves, and customers start complaining about wobbly twists. The rotating mechanism—the heart of the tube—starts to loosen up after a few uses. Why? Often, it’s because the adhesive couldn’t keep up with the constant motion. In one factory run I heard about, they lost 15% of a shipment to this issue alone during quality checks. Twisting forces pull at the bond between the plastic base and metal shell, and if the glue lacks grip, it’s game over.

But here’s the kicker. A solid lipstick tube hot melt adhesive changes that. With strong adhesion to materials like ABS, aluminum, and PS, it locks those parts in place. Think of it as a tough grip that doesn’t quit. Banglin’s formula, for instance, is built for this—its synthetic rubber base delivers lasting hold, tested to withstand thousands of rotations without budging. Apply it at 150-180°C, and you’ve got a bond that laughs off daily wear. No more loose parts; just smooth, reliable twists that keep your brand looking pro.

Quick Tips to Avoid This

-

Check substrate cleanliness—oils or dust kill bonds fast.

-

Use enough adhesive; skimping leads to weak spots.

-

Test with torque tools to mimic real use.

Failure 2: Debonding in Cold Temperatures

Cold weather shipping? It’s a nightmare for adhesives that aren’t up to snuff. Imagine tubes sitting in a refrigerated truck, and boom—the glue gives way, causing the base to pop off. This hits hard in winter markets or global exports. From what I’ve seen in industry chats, failure rates can spike by 20-25% if the adhesive isn’t cold-resistant. The problem? Standard glues get brittle below freezing, losing their flex.

Enter a lipstick tube hot melt adhesive designed for extremes. These bad boys stay flexible even in the chill, thanks to heat and cold resistance baked right in. We’re talking stability from sub-zero storage to steamy bathrooms. A good one softens at 80-100°C but holds firm way below that. In a real scenario, a cosmetics line switched to this type and cut cold-debonding complaints by half. It wets the surfaces perfectly during application, creating a seal that endures temperature swings. Result? Tubes that travel anywhere without a hitch.

Failure 3: Adhesive Overflow Affecting Appearance

Overflow is sneaky. It happens when glue squeezes out during assembly, leaving sticky blobs or smears on the tube’s exterior. Not only does it mess with the sleek look—think fingerprints or dust magnets—but it can gum up packaging machines too. I recall a small run where overflow led to 10% rework, just because the adhesive was too runny at high speeds.

The fix? Opt for a no-stringing lipstick tube hot melt adhesive. These are engineered to flow clean, with viscosity around 700-2000 cps at 180°C. No drips, no mess. Apply it right, and it sets fast without spilling over edges. For aluminum-to-plastic bonds, this keeps things tidy and professional. Factories report smoother lines and fewer visual defects, boosting that premium vibe your customers crave. It’s all about control—get the temp spot-on, and overflow becomes a thing of the past.

Common Causes of Overflow

-

Too high application heat, making it too fluid.

-

Worn nozzles letting extra glue escape.

-

Pressing too hard without timing the set.

Failure 4: Weak Bonds Leading to Separation During Transport

Transport jostles everything. Bumps, vibrations— they test bonds to the limit. Weak adhesives crack under pressure, causing components to separate mid-shipment. One exporter shared how this wrecked a whole container, with tubes arriving in pieces. Stats? Up to 30% loss in rough handling if the glue isn’t durable.

A top-notch lipstick tube hot melt adhesive steps up here. Its long-lasting bond grabs hold of PVC, PET, and composites, creating a barrier against shakes and drops. Fast setting means it’s rock-solid before packing. In practice, brands using these see fewer returns, with bonds holding through thermal cycles and rough roads. It’s not magic; it’s smart chemistry that matches the tube’s materials perfectly. Clean surfaces and timely pressing seal the deal—literally.

Failure 5: Stringing on High-Speed Production Lines

Stringing? That’s when adhesive pulls into threads like cheese on pizza, clogging machines and slowing everything down. On fast lines, this can halt production, eating into profits. A buddy in manufacturing mentioned downtime jumping 15 minutes per hour from bad stringing.

The right lipstick tube hot melt adhesive nips this in the bud. Formulated for clean cuts, it prevents those pesky strings even at top speeds. Low viscosity options ensure smooth flow without the mess. Banglin tweaks theirs for automated setups, cutting stringing incidents dramatically. Keep nozzles clean and temps steady, and your line hums along. Efficiency up, costs down—simple as that.

Production Line Hacks

-

Monitor shut-off mechanisms for wear.

-

Adjust temps based on speed—higher for faster runs.

-

Run trials to dial in the sweet spot.

Meet Banglin: Your Go-To Hot Melt Adhesive Supplier

If you’re hunting for reliable fixes, Banglin stands out as a powerhouse in hot melt adhesives. Since 2005, this Hangzhou-based crew has been cranking out top-tier products from their high-tech park. They’re all about innovation—think patented formulas and a killer R&D team with over 30 years under their belts. Banglin specializes in custom hot melts for cosmetics, like those lipstick tube bonds that handle tough jobs. They’ve got the goods: eco-friendly, non-toxic options that boost your production without skimping on quality. Serving thousands of clients worldwide, they’re the partner who gets your back with tailored solutions and solid support.

Conclusion

Wrapping it up, dodging these assembly pitfalls isn’t rocket science—it’s about smart choices. A quality lipstick tube hot melt adhesive tackles loose parts, cold snaps, messy overflows, shaky transports, and stringy slowdowns head-on. It keeps your products sharp, your lines efficient, and your brand shining. Dive in, test it out, and watch the difference.

FAQs

What makes lipstick tube hot melt adhesive ideal for rotating mechanisms?

Lipstick tube hot melt adhesive shines here because of its strong, flexible hold. It bonds metals and plastics without loosening over time, even with daily twists. From our experience, it cuts failure rates in motion-heavy parts by keeping everything snug.

How does lipstick tube hot melt adhesive handle cold storage without debonding?

This stuff is built tough for temps. Its resistance to cold prevents brittleness, so tubes stay intact during chilly shipments. Think reliable bonds that don’t crack—perfect for global distribution.

Can lipstick tube hot melt adhesive prevent overflow and keep tubes looking clean?

Absolutely. With no-stringing formulas, it applies neat without spills. That means flawless aesthetics, no rework, and products that pop on shelves.

Why choose lipstick tube hot melt adhesive for high-speed assembly lines?

It sets fast and flows clean, ditching stringing that bogs down machines. Factories see smoother runs and higher output, making it a game-changer for busy ops.

Is lipstick tube hot melt adhesive customizable for specific tube materials?

Yep, it adapts to ABS, aluminum, PVC, and more. Tailor it to your setup for bonds that last, boosting durability across the board.