How to Prevent Courier Bag Bursting and Tampering During Transit

In the fast-moving world of online shopping and shipping, one ripped courier bag or one sneaky tampered package can quickly turn a good delivery into a real mess. Imagine a customer tearing open their eagerly awaited order, only to discover damaged goods or missing pieces. For any business, that spells trouble: refunds pile up, angry reviews spread fast, and your good name takes a beating. The bright side? Most of these headaches come straight from seals that simply aren’t tough enough for the journey. Picking the right courier bag hot melt adhesive makes all the difference. It builds a rock-solid, tamper-evident closure that stands up to everything from rough handling to wild weather.

Why Courier Bags Burst or Get Tampered With in the First Place

Shipping can be brutal. Boxes tumble onto belts. They stack high in trucks. They squeeze through sorting machines. And they face big temperature swings along the way. Several things usually cause bags to burst open:

- Too much stuff crammed inside, or items poorly balanced — everything shifts and pushes hard against the seal.

- Glue or tape that just isn’t strong enough — it loses its grip when things get hot, cold, or bumpy.

- Film that stretches or tears — if the bond isn’t solid, the material gives way under stress.

Then there’s tampering. A weak seal lets someone slip in, take something out, slip in a fake item, and close it back up without leaving a trace. Industry folks and shipping reports keep pointing out the same thing: bad seals sit right at the top of damage claims. One logistics breakdown showed that weak closures alone cost mid-sized online stores thousands in avoidable returns every single year.

The damage hurts in real ways. Refunds cut straight into profits. Restocking eats more money. And upset customers leave harsh reviews that drive others away. That’s exactly why so many companies are moving to specialized adhesives built just for these tough situations.

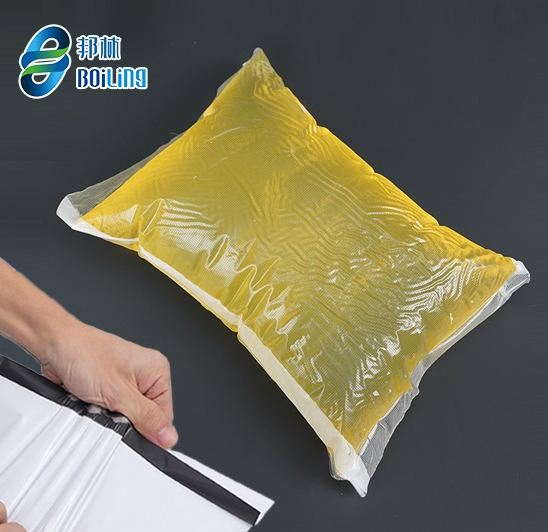

The Power of Pressure-Sensitive Hot Melt Adhesive for Courier Bags

Courier bag hot melt adhesive is no ordinary glue. This pressure-sensitive kind melts fast. It spreads easily on fast-moving lines. And once it cools down, it locks in place with serious strength. Here’s what really sets it apart for express packaging:

- It grabs the surface instantly — sticks tight to PE or PP film the second it touches.

- It shows tampering clearly — try to peel it open after it sets, and you’ll see the film rip or the glue layer tear apart. No hiding the attempt.

- It handles heat and cold well — stays firm through scorching summer trucks or freezing winter nights.

- It lasts a long time — the bond holds steady for weeks, even months, whether the package sits in a warehouse or bounces around in transit.

In everyday use, this adhesive shines on bubble mailers, plain plastic courier bags, and even paper envelopes. People running high-speed bag machines really like how clean it runs. No annoying strings. No clogs. And it sets quick enough to keep everything moving smoothly.

Think about a busy e-commerce warehouse pumping out thousands of parcels daily. With weaker glues, they often see 2–5% of bags fail during rough drop tests or bumpy rides. Switch over to a solid courier bag hot melt adhesive, and that number drops hard. Fewer complaints roll in. Return rates shrink. Customers stay happy and keep ordering.

Key Features That Make a Difference in Transit

When you’re shopping for adhesive for courier bags, keep an eye on these things:

- Base material— Synthetic rubber formulas give the nicest mix of toughness and flex.

- Viscosity and application temp— Roughly 1500 cps at 180°C means it coats smoothly without making a mess.

- Softening point— Around 90°C keeps everything stable even in hot warehouses or steaming trucks.

- Bond strength— A permanent grip that fights off shear and peel forces from shifting packages.

These details turn into real benefits on the road:

- Bags survive hard drops and constant shaking without splitting open.

- Seals stay put through wild temperature changes, from -10°C to 50°C.

- Any tampering attempt leaves obvious marks, which scares off thieves and makes problems easy to spot early.

Plenty of logistics teams say that moving to this kind of adhesive cuts damage-related returns by 30–50%. That’s serious cash saved on refunds and a lot less stress about protecting the brand.

How to Implement It in Your Packaging Process

Switching over isn’t complicated, especially when you already run automated gear. You melt the hot adhesive and lay it down in a neat slot or strip along the sealing flap. It bonds fast under light pressure and hardens quickly.

A few practical pointers from folks who do this every day:

- Test your film first. Different PE or PP blends behave a little differently. Run a small test batch to be sure.

- Watch the amount you apply. Too little creates weak spots. Too much wastes material and might ooze out.

- Keep operators trained. Steady temperature and consistent speed stop uneven patches.

- Keep an eye on real shipments. Track returns for a few weeks after the switch to see the improvement.

Once everything is tuned, the whole line runs cleaner than tape. You waste less material. And you push more bags through in the same time.

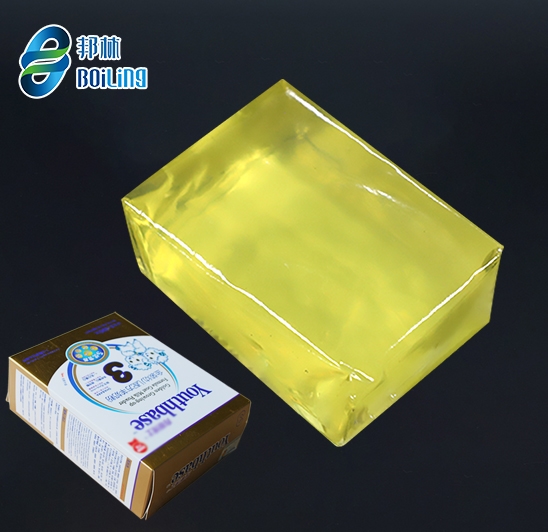

About Banglin: A Trusted Hot Melt Adhesive Supplier

Banglin (from Hangzhou Boiling Adhesive Technology Co., Ltd.) has been a solid player in hot melt adhesives since 2005. As a national high-tech company, they focus on pressure-sensitive hot melt products made especially for logistics and packaging needs. Their courier bag hot melt adhesive stands out because it delivers reliable tamper-evident strength, excellent grab on plastic films, and dependable results in high-volume express work. They offer custom blends, steady quality, and full support for ODM/OEM projects. Banglin helps companies create packaging that survives the trip and keeps their brand safe.

Conclusion

In the tough, competitive world of e-commerce today, good packaging isn’t just nice to have — it’s a must. When you pick a strong courier bag hot melt adhesive, you tackle the main reasons for bursting and tampering right at the source. You end up with far fewer damaged deliveries. You spend less on returns and refunds. You build stronger trust with customers. And you earn a reputation for delivering exactly what you promise. A small upgrade in sealing can bring big protection for your products and your profits.

FAQs

What makes courier bag hot melt adhesive better than regular tape for stopping tampering?

It forms a permanent bond that screams if someone tries to open it. Once sealed, any attempt rips the film or tears the adhesive layer, so tampering becomes impossible to hide.

Can courier bag hot melt adhesive deal with crazy temperature swings during shipping?

Yes, it does. Good versions stay solid in blazing heat above 50°C and stay tough in freezing cold below -10°C. No softening. No cracking.

How does strong adhesion from courier bag hot melt adhesive cut down on return costs?

Fewer bags burst open or get tampered with means fewer damaged or stolen orders. Many companies see return rates drop 30–50%, saving money on refunds, restocking, and brand headaches.

Is courier bag hot melt adhesive simple to use on fast automated bag-making lines?

Definitely. It spreads clean through slot or strip methods, sets fast, and runs without strings or jams — perfect for high-speed production.

What kinds of bags does courier bag hot melt adhesive work well on?

It sticks great to plastic courier bags, bubble mailers, PE and PP films, paper envelopes, and even insulated thermal bags used for food delivery.