What Is Beverage Carton Hot Melt Adhesive and Why It’s Critical for Packaging Integrity

Beverage cartons take a beating. They stack high in warehouses. They ride bumpy trucks. They sit in fridges or on hot loading docks. One thing keeps them from popping open or leaking: the right adhesive. Beverage carton hot melt adhesive seals those flaps tight. It holds through the whole supply chain. For packaging plants running high-speed lines, the wrong glue means downtime, waste, and angry customers. The right one keeps everything moving smoothly and the product safe inside.

This guide breaks down what beverage carton hot melt adhesive really does. We look at how it works in real carton sealing. We cover the must-have performance traits. And we explain why those details matter when you’re buying or specifying for production.

What Exactly Is Beverage Carton Hot Melt Adhesive?

Beverage carton hot melt adhesive is a thermoplastic glue. You melt it, apply it hot to paperboard flaps, and press the carton closed. It sets fast as it cools. No water or solvents to evaporate. That quick set is why high-speed machines love it.

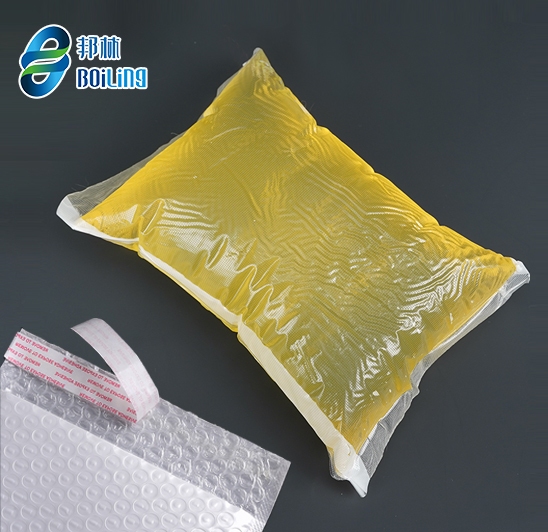

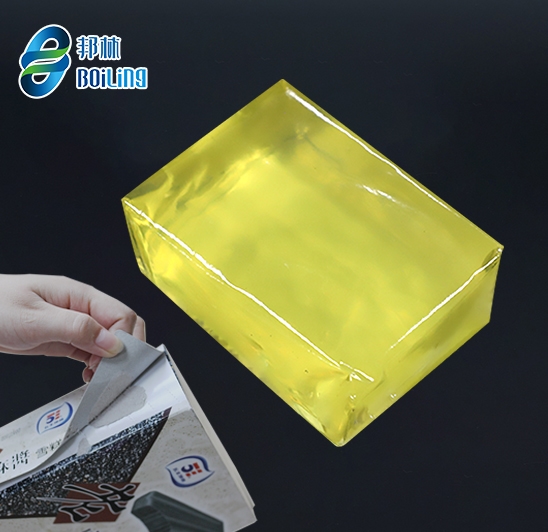

Most formulas today use synthetic rubber bases. They come in yellow blocks. Easy to load into melters. Once applied, the bond grabs hard on kraft, coated, or laminated surfaces common in beverage cartons. The glue stays flexible after cooling. No cracking when the carton gets squeezed or folded during filling and stacking.

Unlike pressure-sensitive types for tapes or labels, these packaging hot melts focus on fast closure and long-term hold. They suit automated carton erectors and sealers in beverage plants. Think aseptic brick packs for juice, milk, or energy drinks. The adhesive has to handle cold fills, then warm storage, without letting go.

How It Works in Real Beverage Packaging Lines

On a typical line, cartons form from flat blanks. Glue guns shoot beads or dots onto the bottom and side flaps. The machine folds and compresses right away. Good beverage carton hot melt adhesive sets in seconds—often under five. That lets the line push 100+ cartons a minute without waiting.

After filling and top sealing (sometimes ultrasonic or another method), the carton goes through shrink wrapping or palletizing. The adhesive faces shear from stack weight. It deals with temperature swings: cold from refrigeration, heat from summer trailers. A solid formula keeps flaps shut. No leaks. No product loss.

Real-world example: A juice bottler runs 24/7. One shift switches to a new adhesive batch. If open time is too short, flaps don’t close fully before set—weak seals. Too long, and compression timing throws off. Either way, rejects climb. Plants that nail the open time and set speed cut waste by 20-30% in busy seasons.

Key Performance Properties That Matter Most

When you’re evaluating beverage carton hot melt adhesive, zero in on a few core specs. These directly hit line efficiency and package reliability.

- Initial Tack / Grab: How quick and strong the first bond forms on contact. High initial grab lets flaps stick without heavy pressure. Crucial for high-speed folders where dwell time is short.

- Open Time: The window the glue stays molten and workable after application. Usually 5-15 seconds for beverage lines. Too short and you miss alignment. Too long and cartons shift before set.

- Set Time: How fast it hardens enough to hold. Fast set (2-5 seconds) keeps lines flying. Slower ones suit manual or slower semi-auto setups.

- Shear Strength: Resistance to sliding forces. Stacked pallets push down hard. Good shear stops flaps from creeping open over weeks in storage.

- Temperature Resistance: Service range matters. Beverages often go from cold fill (around 4°C) to ambient or warm transport (up to 50°C+). The bond shouldn’t soften or get brittle.

- Viscosity at Application: Typically 1500-3500 cps at 150-180°C. Flows clean through nozzles. No stringing or charring in melters.

- Adhesion to Substrates: Bonds well to treated or coated boards without delamination. Many beverage cartons use polyethylene-lined or foil-laminated paperboard.

Quick comparison table for what buyers check:

|

Property |

Typical Range for Beverage Carton Use |

Why It Matters on the Line / In Use |

|

Open Time |

5–15 seconds |

Matches machine speed; prevents misalignments |

|

Set Time |

2–8 seconds |

Enables high throughput without weak seals |

|

Shear Strength |

High (holds under stack loads) |

Prevents failures in palletized storage/transport |

|

Application Temp |

150–180°C |

Works with standard hot melt equipment |

|

Service Temp Range |

-10°C to +60°C or wider |

Survives cold chain to hot distribution |

|

Viscosity @ 180°C |

1500–3500 cps |

Clean application, no clogging |

Test these in your own setup. Run pilot cartons through your filler, stack them, chill them, then heat cycle. Real failures show up there—not just on spec sheets.

Common Challenges and How the Right Adhesive Solves Them

Beverage plants face tricky spots. Coated boards resist glue. Cold fills condense moisture. High humidity slows set. A forgiving beverage carton hot melt adhesive wets those surfaces fast. It tolerates slight dampness without losing bond.

Another headache: seasonal changes. Winter warehouses drop below freezing. Summer trailers bake. Adhesives with wide temp windows hold steady. No pop-opens in January cold storage. No oozing in July heat.

Line operators hate stringing or char. Clean-running formulas cut maintenance. Less downtime. One plant switched to a low-odor, stable melt and dropped nozzle cleans from daily to weekly.

Food safety sits top of mind. Many modern beverage carton hot melt adhesives meet REACH and food-contact basics. Low migration. No funky smells that taint product.

Introducing Banglin as a Hot-Melt Adhesive Products Supplier

Banglin (Hangzhou Boiling Adhesive Technology Co., Ltd.) has built hot-melt adhesive blocks since 2005 out of Hangzhou Future Science Industrial Park. As a national high-tech enterprise, they run a solid R&D setup with imported rheometers and experienced engineers.

They specialize in pressure-sensitive and packaging hot melts. That includes dedicated options like paper carton hot melt adhesive suited for beverage carton sealing. Their range covers carton closure, express bags, tapes, labels, and more. They offer custom ODM/OEM services straight to packaging manufacturers. Custom formulas match exact substrates, speeds, and conditions.

Processes stay traceable batch to batch. Colors, block sizes (from small to pallet loads), and packaging get tailored. Minimums start at 2000 kg. One-on-one support helps tweak performance for beverage lines without starting from scratch.

Conclusion

Beverage carton hot melt adhesive does more than just stick flaps. It keeps the whole package reliable—from fast-fill lines to store shelves. Get the grab, open time, shear, and temp handling right, and your cartons stay sealed. Leaks drop. Waste shrinks. Customers stay happy.

Take time to match the adhesive to your substrates, machines, and distribution chain. Test rigorously. Work with suppliers who know packaging inside out. When the glue performs quietly every run, your operation runs smoother and your brand holds stronger.

FAQs

What is beverage carton hot melt adhesive, and how does it differ from other packaging glues?

Beverage carton hot melt adhesive is a fast-setting thermoplastic glue made for sealing paperboard beverage cartons. It grabs quick on coated or laminated surfaces, sets in seconds, and holds under cold-to-hot swings. Unlike slower case sealers or pressure-sensitive labels, it focuses on high-speed closure and durable bonds that prevent leaks in filled, stacked packs.

Why does open time matter so much when choosing beverage carton hot melt adhesive?

Open time is the window the glue stays workable after application. On fast beverage lines, 5-15 seconds lets flaps align and compress properly before set. Too short, and seals fail from poor contact. Too long, and cartons shift. Matching it to your machine speed cuts rejects and keeps output high.

How does shear strength affect beverage carton performance in real distribution?

Shear strength stops flaps from sliding under stack pressure or vibration. Palletized beverage loads face constant downward force during transport. Strong shear keeps seals intact—no pop-opens in warehouses or trucks. Weak shear leads to leaks and returns.

Can beverage carton hot melt adhesive handle food-contact requirements?

Many current formulas meet basic food-contact standards like REACH compliance with low migration. They’re low-odor and designed not to taint contents. For beverage use, pick ones labeled food-safe to stay on the safe side with regulations and brand trust.

What should packaging manufacturers look for when testing new beverage carton hot melt adhesive?

Run trials on your actual boards and machines. Check initial grab on contact, set speed under compression, bond strength after cold storage and heat exposure. Simulate stacking, drop tests, and humidity. Consistent performance across batches means fewer line stops and better package integrity down the road.