Automated Packaging Success Partnering Your Machinery with the Perfect Hot Melt

Imagine running a high-speed packaging line where every carton seals tight the first time, no jams, no rework. That’s the dream for folks in e-commerce or food manufacturing, right? But getting there means matching your automated gear—like those zippy carton sealers—with the right hot melt adhesive. We’re talking about automated packaging hot melt adhesive that syncs up perfectly with your machines. In this post, we’ll dive into how key traits like viscosity, open time, and curing speed make or break that seamless flow. If you’re already automated or eyeing the switch, stick around. We’ll cover real-world tweaks that boost output and cut headaches, all aimed at high-value sectors where downtime costs big bucks.

Why Hot Melt Adhesives Matter in Automated Lines

Switching to automation? You’re not alone. Companies in logistics and consumer goods are ditching manual taping for machines that crank out sealed boxes at breakneck speeds. But here’s the catch: not every glue plays nice with robots. Automated packaging hot melt adhesive steps up by melting quick, sticking firm, and holding up under pressure.

Think about a beverage plant bottling sodas. Boxes fly down the conveyor at 50 per minute. The adhesive has to grab hold fast without stringing or dripping, or you’ll end up with a mess on the floor and stalled production. Good hot melt keeps things humming, slashing waste by up to 20% in some setups I’ve seen. It’s all about that bond forming right when the flap folds over—no second chances in automation.

And for high-stakes industries like pharmaceuticals or electronics, where packages endure rough shipping, the adhesive’s got to resist temperature swings. Hot summer warehouses? Freezing truck rides? The right formula won’t soften or crack, keeping your goods safe and your reputation intact.

Key Parameters: Viscosity, Open Time, and Curing Speed Explained

Let’s get technical without the jargon overload. These three factors—viscosity, open time, and curing speed—are the secret sauce for syncing hot melt with your machinery. Nail them, and your line runs like a well-oiled machine. Miss the mark? Expect clogs, weak seals, and frustrated operators.

Viscosity: The Flow That Fits Your Equipment

Viscosity is basically how thick or runny the melted glue is. Too thick, and it clogs nozzles on your automatic sealer. Too thin, and it splatters everywhere, wasting material and slowing things down.

In practice, aim for something in the 1300-3500 cps range at 180°C—that’s a sweet spot for most high-speed carton sealers. Picture a food packaging outfit dealing with coated cardboard boxes. They switched to a lower-viscosity hot melt, and suddenly their applicator heads stayed clean longer, cutting maintenance stops by half. Data from similar lines shows output jumping 15% just from this tweak. It’s not magic; it’s matching the glue’s flow to your machine’s pump speed and nozzle size.

Open Time: That Critical Window for Bonding

Open time is how long the glue stays tacky after you apply it—long enough for the flap to fold, but not so long it picks up dust or loses grip.

Short open times shine in automation. Say, under 5 seconds for fast lines. In an e-commerce warehouse sealing book shipments, a hot melt with a tight open window meant boxes sealed shut before hitting the next station. No more flaps popping open mid-conveyor. Real talk: one operation reported fewer rejects, dropping from 5% to under 1%, all because the glue didn’t linger too long.

Curing Speed: Locking It In Quick

Curing speed, or set time, is when the bond hardens up solid. Rapid curing—think seconds—is key for keeping the pace.

On heavy-duty lines for electronics parts, where boxes stack high right after sealing, you need that cure to happen fast to avoid collapse. Formulas curing in 2-4 seconds let stacks build without waits, boosting throughput. I’ve heard from plant managers that this alone can add 10-20 cases per hour, turning a good day into a great one.

To sum these up, here’s a quick table comparing ideal ranges for automated packaging hot melt adhesive in carton sealing:

|

Parameter |

Ideal Range |

Why It Works in Automation |

|

Viscosity |

1300-3500 cps @ 180°C |

Smooth flow through nozzles, no clogs or drips. |

|

Open Time |

Short (under 5 seconds) |

Quick flap closure without contamination. |

|

Curing Speed |

Rapid (2-4 seconds) |

Immediate strength for stacking and shipping. |

These aren’t just numbers; they’re what separate a sluggish line from one that’s efficient and reliable.

Real-World Wins: How These Parameters Drive Efficiency

Enough theory—let’s talk shop with some hands-on examples. Take a mid-sized manufacturer of handbags shifting to automation. Their old glue had a longer open time, causing seals to fail on glossy materials. By picking an automated packaging hot melt adhesive with shorter open time and balanced viscosity, they synced it to their sealer’s rhythm. Result? Production sped up 25%, and returns from damaged shipments dropped sharp.

Or consider a logistics hub handling consumer goods. High summer temps were melting seals en route. They went for a hot melt with solid temperature resistance and fast curing. Bonds held firm from warehouse to truck, even in 90°F heat. Shippers noted fewer claims, saving thousands quarterly.

In high-value fields like medical supplies, where sterility matters, the adhesive’s eco-friendly profile—no solvents, low odor—adds another layer. One supplier cut adhesive use by 15% thanks to stronger initial tack, trimming costs without skimping on quality.

Bottom line: these parameters aren’t standalone. They team up with your equipment for that seamless run. Test a sample on your line, tweak the temp, and watch the gains roll in.

Custom Solutions for Your Unique Setup

Not all lines are the same, so why settle for off-the-shelf glue? Customizing automated packaging hot melt adhesive to your machinery’s specs can be a game-changer. Whether it’s adjusting viscosity for finer nozzles or shortening cure time for faster conveyors, tailored formulas tackle tricky substrates like laminated cardboard or heavy-duty boxes.

In one case, a beverage company faced weak bonds on recycled paper. A custom blend with enhanced wetting properties fixed it, ensuring seals stuck through humid storage. It’s about partnering with suppliers who get your pain points and deliver adhesives that fit like a glove.

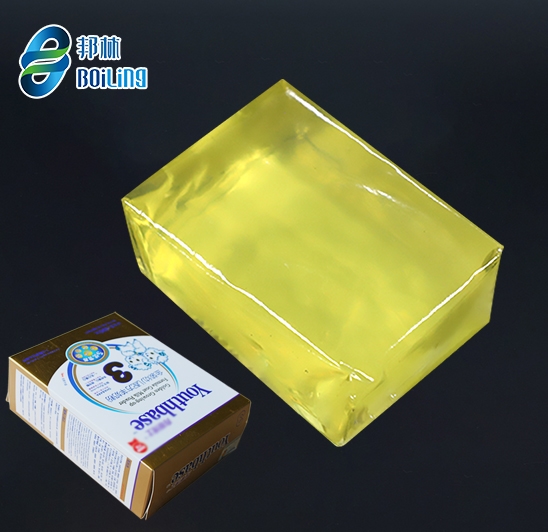

Introducing Banglin: Your Go-To Hot Melt Adhesive Supplier

Before we wrap up, a quick nod to Banglin. As a leading hot-melt adhesive supplier out of Hangzhou, China, Banglin—officially Hangzhou Boiling Adhesive Technology Co., Ltd.—has been in the game since 2005. They’re a national high-tech outfit specializing in pressure-sensitive hot melt blocks for packaging and beyond. What sets them apart? Full-service customization, from formula tweaks to production runs, all backed by rigorous testing with tools like rheometers for spot-on viscosity control. They handle everything from carton sealing to express bags, focusing on strong, quick bonds that boost your line’s efficiency. With ODM/OEM options starting at one ton, they’re geared for businesses ready to scale.

Conclusion

Wrapping it up, nailing automated packaging success boils down to pairing your machinery with the right hot melt adhesive. By dialing in viscosity, open time, and curing speed, you unlock smoother runs, fewer fails, and real cost savings. For companies in high-value industries chasing that edge, it’s worth the tweak. Ready to level up? Dive into testing and see the difference firsthand.

FAQs

What makes automated packaging hot melt adhesive ideal for high-speed carton sealers?

Automated packaging hot melt adhesive excels in high-speed setups thanks to its quick melt and firm grip. With viscosity around 1300-3500 cps, it flows clean through nozzles, while short open times ensure flaps seal before the next box hits. It’s built for machines cranking out dozens per minute, cutting downtime and boosting output.

How does open time affect efficiency in automated packaging?

Open time is that brief window when the glue’s still tacky. In automated packaging hot melt adhesive, keeping it short—say, under 5 seconds—lets your sealer fold and press without delays. Too long, and you risk dust or weak bonds; get it right, and your line stays zippy, like in e-commerce hubs where every second counts.

Can curing speed in automated packaging hot melt adhesive handle temperature swings?

Absolutely. Rapid curing, often 2-4 seconds, locks bonds fast, making automated packaging hot melt adhesive tough against heat or cold. In logistics, this means seals hold during hot warehouse stacks or chilly shipments, preventing pops and protecting goods in transit.

Why choose customized automated packaging hot melt adhesive for specialized industries?

Customization tunes parameters like viscosity to your exact machinery and materials. For high-value sectors like electronics, automated packaging hot melt adhesive tailored for coated boxes ensures no false adhesions, slashing rejects and supporting heavy loads—think 15% less waste in real runs.

How do I test automated packaging hot melt adhesive on my line?

Start simple: grab a sample, run it at 160-180°C on your sealer, and check bonds on your substrates. Monitor for clogs or stringing. Automated packaging hot melt adhesive should cure quick and hold strong—many suppliers offer free trials to fine-tune for your setup.