The Ultimate Guide to Pressure-Sensitive Adhesives for Label Manufacturing

Label producers face constant pressure to deliver flawless results. A label that curls at the edges damages brand image. Residue left behind annoys end users. In extreme cases, a detached warning label on a hazardous container raises serious safety concerns. Pressure-sensitive adhesives lie at the core of these issues. They create bonds through simple contact. No additional heat or curing period is required. On today’s high-volume converting lines that process thousands of feet per hour, these adhesives determine whether operations run smoothly or encounter frequent interruptions. This guide examines their role in label production, performance on various materials, and factors that lead to consistent, dependable results.

How Pressure-Sensitive Adhesives Work in Labels

Pressure-sensitive adhesives remain sticky at ordinary temperatures. Light finger pressure activates immediate attachment. Manufacturers apply them in hot-melt form to silicone release liners or directly to label stocks. This method supports clean, rapid processing on modern equipment.

Labels encounter widely varied environments. Some endure refrigerated storage. Others conform to rounded containers. Certain types withstand outdoor elements or chemical exposure. Effective PSAs maintain balance across initial grab, lasting hold, and ability to tolerate temperature changes. When these properties align properly, labels stay secure from production through final use.

Practical experience highlights the impact. Converting lines frequently operate at 300 to 600 feet per minute. Incompatible adhesives lead to frequent web breaks or inconsistent die cuts. Adopting suitable hot-melt PSAs often reduces machine stops by 20 to 40 percent in typical facilities.

Key Performance Factors for Label Adhesives

Substrate type and final application dictate specific adhesive behavior.

Initial Tack on Various Face Stocks

Initial tack governs how quickly a label adheres during dispensing. Smooth PET surfaces demand rapid bonding from the applicator. Textured kraft paper requires the adhesive to flow into rough areas promptly.

Rubber-based compositions provide aggressive early grab. They suit paper and board materials well. Acrylic types develop tack more gradually yet excel on plastic films over time.

Holding Power and Shear Strength

Holding power prevents labels from lifting after application. Tire labels experience repeated flexing. Freezer labels face heavy moisture buildup. Shear resistance exceeding 500 minutes on standard tests generally indicates dependable long-term performance.

One distribution center monitored edge lift on carton labels. After changing to a higher-shear PSA, reported failures fell 85 percent across several months.

Temperature Resistance

Labels operate in harsh thermal conditions. Food products in cold supply chains require adhesion at -20°F or lower. Containers stored outdoors may reach 140°F under direct sunlight.

Formulas designed for low temperatures remain pliable in freezers. Heat-stable versions resist flow during warm processing or storage.

The table below outlines typical requirements by material:

|

Substrate |

Key Challenge |

Needed PSA Traits |

Typical Peel Strength |

|

PE Film |

Low surface energy |

Strong initial grab, pliability |

3-6 N/25mm |

|

PP Film |

Similar to PE, often recycled |

Good surface wetting, cold tolerance |

4-7 N/25mm |

|

PET |

Smooth, high energy |

Permanent attachment, clarity |

5-8 N/25mm |

|

Paper |

Porous, variable texture |

Quick attachment, no bleed |

2-5 N/25mm |

PE and PP films present adhesion difficulties due to low surface energy. Carefully developed hot-melt PSAs overcome this without additional surface preparation.

Common Label Applications and Adhesive Choices

Actual production scenarios demonstrate these properties in practice.

Food and Beverage Labels

Transparent “no-label look” containers require completely clear adhesives on PET stock. The material must remain invisible despite moisture exposure. Cold storage demands further resistance to condensation.

One bottled water producer adopted a clear hot-melt PSA. Edge lift under refrigeration disappeared entirely. Converting speeds increased 15 percent because equipment stayed cleaner longer.

Cold Chain and Freezer Labels

Frozen goods packaging operates well below freezing. Ordinary adhesives become rigid and lose grip. Low-transition-temperature compositions preserve flexibility and tack in severe cold.

Supermarket chains observe far fewer failures in frozen display cases after selecting cold-tolerant PSAs. Associated rework expenses decline substantially.

Chemical and Industrial Labels

Hazardous material containers encounter oils, solvents, and weather. Labels need durable acrylic PSAs that resist chemical migration and discoloration.

A chemical facility evaluated outdoor drum labels. After six months of exposure, 98 percent of labels applied with the improved PSA remained fully intact. Previous materials achieved only 60 percent retention.

Transparent and High-End Cosmetic Labels

Luxury cosmetics demand perfect visual appearance. Clear films on glass or plastic require adhesives that vanish completely. Production also benefits from easy release during fixture handling.

Cosmetic converters often manage short runs. Versatile hot-melt PSAs compatible with multiple substrates reduce setup time between jobs.

Advantages of Hot-Melt Pressure-Sensitive Adhesives

Hot-melt PSAs deliver tangible benefits in label converting plants.

- Absence of solvents creates cleaner, safer work areas.

- Immediate bonding accelerates coating and finishing steps.

- Full solids content minimizes material waste.

- Simple storage eliminates complex mixing procedures.

Many converters achieve 30 to 50 percent faster coating rates compared to solvent-based systems. Energy consumption drops as well, since large drying ovens stay idle.

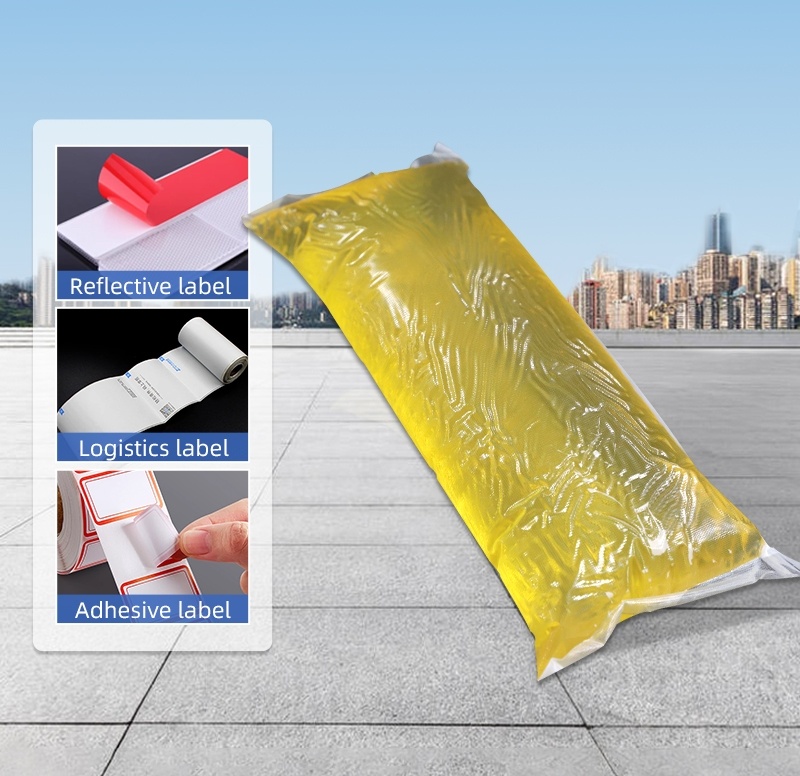

Introducing Banglin: Your Trusted Hot-Melt Adhesive Supplier

Banglin has established itself as a respected supplier of hot-melt adhesives since 2005. Based in Hangzhou, China, this advanced enterprise develops sophisticated pressure-sensitive products for labeling and related industries. Its dedicated research facility produces custom compositions that address challenging materials such as PE, PP, and PET. Banglin adhesives comply with rigorous international requirements including REACH and RoHS. With annual capacity reaching 25,000 tons, the company supports global customers and provides tailored solutions for demanding label applications. Banglin enables converters to produce labels that perform reliably under diverse conditions.

Conclusion

Pressure-sensitive adhesives serve as the foundation for effective label manufacturing. Appropriate formulations manage varied substrates from paper to plastics and withstand practical challenges like freezing temperatures or chemical contact. Robust initial tack, durable holding power, and suitable temperature tolerance keep labels attractive and securely attached. As consumer brands seek improved clarity, greater durability, and enhanced sustainability, these adhesives continue to advance. Collaboration with knowledgeable suppliers makes possible custom developments that match specific equipment and end-use requirements while raising overall product quality.

FAQs

What makes pressure-sensitive adhesives suitable for high-speed label application?

Pressure-sensitive adhesives attach immediately under light contact and eliminate drying periods. This supports rapid, trouble-free operation on automated dispensing systems.

How do pressure-sensitive adhesives perform on low-energy plastics like PE and PP?

Dedicated compositions spread effectively across low-energy surfaces. They establish strong early grip and lasting bonds without pretreatment. Converters frequently achieve consistent results even on recycled films.

Can pressure-sensitive adhesives withstand freezer temperatures for food labels?

Certain hot-melt types preserve pliability and adhesion well below -20°F. They eliminate edge lift on frozen packaging throughout distribution and retail display.

Are pressure-sensitive adhesives suitable for clear “no-label look” applications?

Transparent acrylic or specialized hot-melt pressure-sensitive adhesives remain completely invisible on PET and glass. They deliver firm attachment while preserving premium package appearance.

How can I get a pressure-sensitive adhesive customized for my label substrates?

Experienced suppliers like Banglin create tailored formulations based on specific materials, equipment speeds, and service conditions. Initial small-scale trials confirm performance before full-scale production.