-

OEM SUPPORTED(MOQ: ≥2000 KG)We offer professional OEM production services for hot melt adhesives. We strictly tailor the production of hot melt adhesives that meet your product requirements, technical specifications and application scenarios. Relying on advanced production equipment and a mature process system, we ensure consistency and reliability in performance such as bonding strength, temperature resistance, and open time for each batch of products. We also support personalized packaging and brand logo customization, helping you quickly expand the market without having to invest in research and development and production resources, and enabling you to have exclusive high-quality hot melt adhesive products.

-

ODM SUPPORTED(MOQ: ≥2000 KG)In addition to OEM manufacturing, we also offer comprehensive ODM solutions for hot melt adhesives. From formula development, application testing to product production, our technical team will deeply analyze your industry requirements and material characteristics, and develop exclusive hot melt adhesive formulas and process flows for you. Whether it's special substrate bonding, environmental certification requirements, or performance optimization in extreme environments, we can provide scientific and reliable solutions to help you create differentiated products and enhance market competitiveness.

CUSTOM WE SUPPORT CUSTOMIZATION

In today's highly competitive hot melt adhesive industry, customers require tailor-made solutions. We understand that each client's production processes, material characteristics, and application environments are unique—just as your customers are not clones, your bonding needs are anything but standard.

We specialize in providing precisely customized hot melt adhesive solutions: whether addressing bonding challenges with specific substrates, meeting performance requirements in extreme working conditions, or complying with eco-certification demands, we develop exclusive formulations for you. Empower your products to stand out in critical metrics such as bond strength, temperature resistance, and application efficiency, building a differentiated competitive edge.

FORMULA CUSTOMIZED FORMULA SERVICE

We offer in-depth customized formula development services, precisely adjusting the formula system according to your specific needs:

-

01Material compatibility customization

-

02Precise parameter control

-

03Customized environmental protection formula

-

04Special functional formula

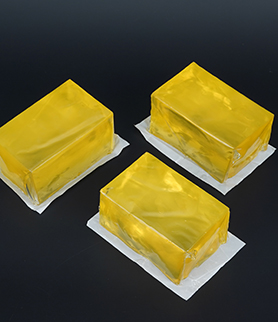

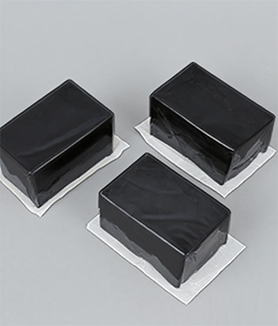

BOILING CHOOSE YOUR COLOUR

We offer professional custom color services for hot melt adhesives. We can precisely mix various colors according to customer requirements, meeting the personalized needs of different industries. We also provide standard color customization: including common colors such as white, black, yellow, and transparent, as well as special effect colors like semi-transparent and milky white.

-

Yellow

-

White

-

Black

-

Yellow transparent

-

White transparent

SPEC Customization of specifications

-

Shape customizationOffer various sizes of adhesive blocks (0.45 - 6.25KG per block)

-

Customization of packaging formSupports customization of packaging form. There are two options available: release film packaging and release paper packaging.

-

Custom packagingWe can provide various packaging options such as carton packaging (15-25kg) and pallet packaging (500-1000kg). We also support customizing the company logo and product information.

CUSTOMIZATION HOW TO CUSTOM

-

1.Demand Alignment and Analysis

Our professional technical advisors will have in-depth one-on-one communication with you. Through detailed technical questionnaires and demand research forms, we will comprehensively understand your application scenarios, substrate characteristics, production processes, and performance requirements. Meanwhile, we can arrange on-site visits by technicians to provide you with precise solution suggestions and product selection guidance.01/04 -

Scheme Design and Sample Preparationand Analysis

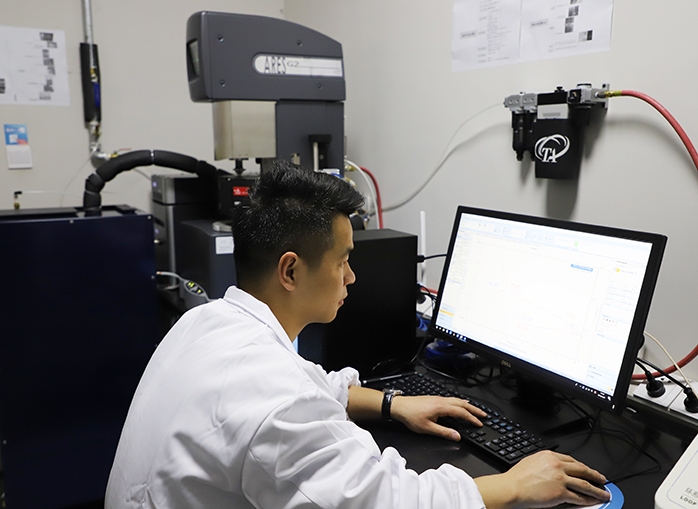

Our experienced R&D team will conduct formula design and optimize process parameters based on the results of demand analysis. Small-batch sample preparation will be completed in advanced laboratories, and a complete technical parameter report and application recommendation will be provided simultaneously to ensure that the samples fully meet your expectations.02/04 -

Testing, Verification and Formula Optimization

Comprehensive performance tests are conducted on samples in a standardized laboratory, covering key indicators such as bonding strength, temperature resistance, and durability. Based on the test data, our engineering team will make precise adjustments to the formula and optimize the process to ensure that the product performance reaches the optimal state.03/04 -

Mass Production Delivery and Continuous Service

We have completed the verification of industrialized production processes, established strict quality control standards and batch traceability systems. We offer stable bulk supply and are equipped with a professional technical team for after-sales tracking. Regular follow-ups on usage are conducted to provide you with continuous technical upgrades and support services.04/04