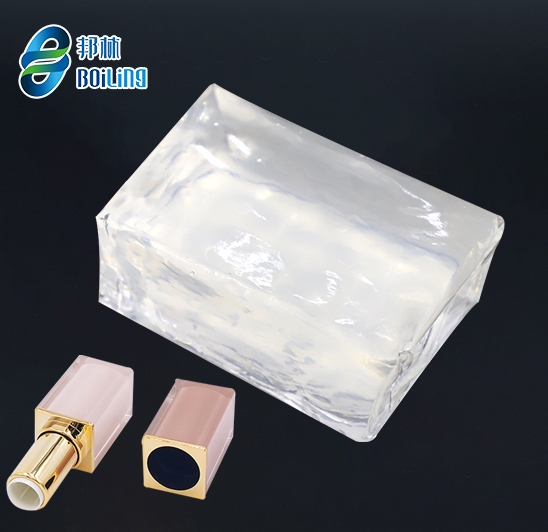

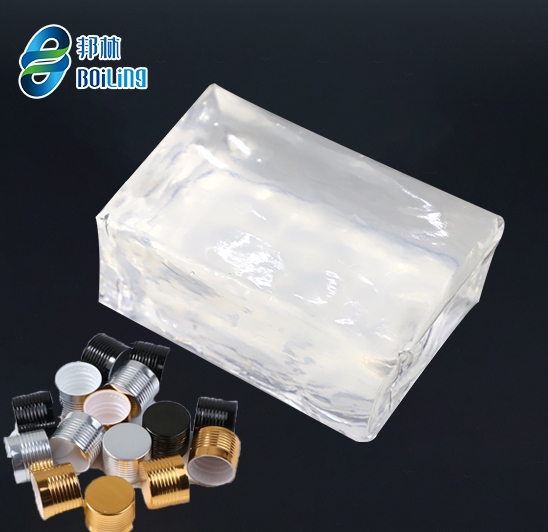

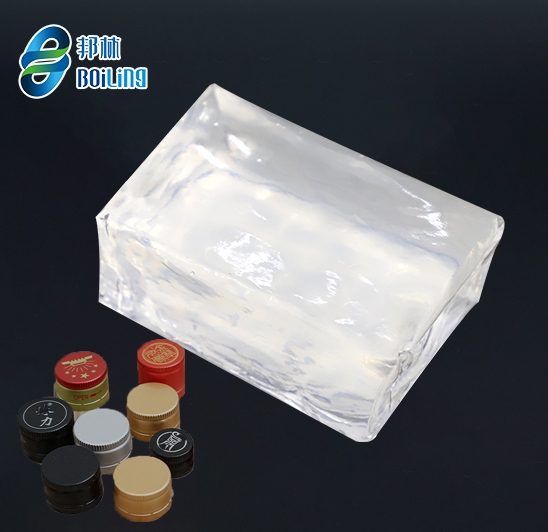

Lipstick Tube Hot Melt Adhesive

Lipstick Tube Hot Melt Adhesive is specially designed for the assembly and bonding of lipstick tubes and cosmetic packaging components.This product is a polyolefin-based hot melt adhesive specifically engineered to address the structural bonding challenges in fine cosmetic packaging such as lipstick and lip balm tubes. It is primarily used for assembling and securing metal (e.g., aluminum) components to plastic parts or plastic-to-plastic components within the tube. Designed for rapid curing, high strength, and excellent finish control, it meets the cosmetics industry’s stringent demands for production efficiency, durable reliability, and high-quality aesthetics.