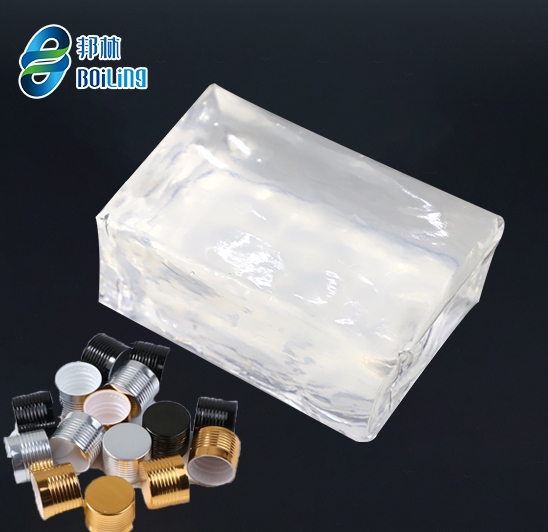

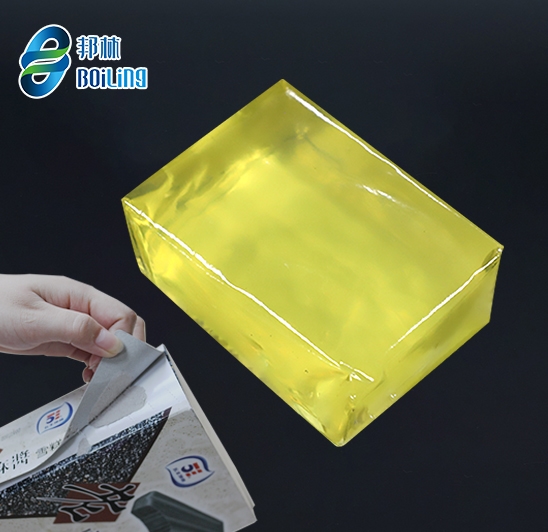

Mattress Hot Melt Adhesive

Hot melt adhesive for mattresses is a functional bonding agent that has been developed to cover the needs of the modern mattress industry in terms of high efficiency, environmental protection, and high-performance production. Its application in mattress manufacturing is quite broad and ranges from bonding non-woven fabric sleeves of individual pocketed springs, laminating multi-layered foams of different densities, and quilted fixation of fabrics and filling layers to the reinforcement of mattress edges. The product’s main property is providing adhesive strength that is both durable and reliable, stabilizing and keeping intact the mattress’s internal structure during long-term use, and consequently, precluding delamination and noise. It is an essential key material for the creation of high-quality, durable mattresses.