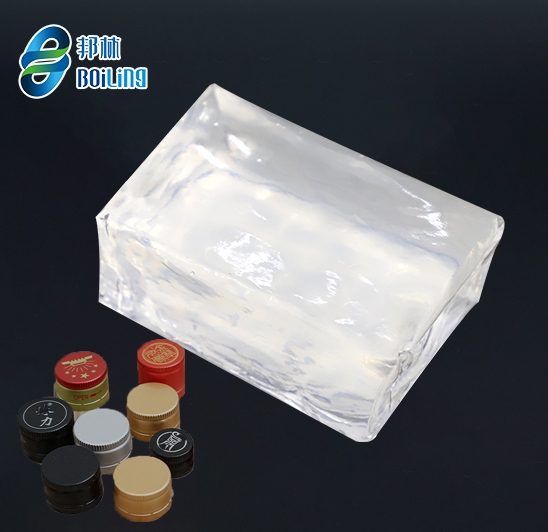

1.Exceptional Bonding Strength

Offers powerful adhesion, securely bonding challenging combinations like plastic to aluminum. On high-speed lines, it grabs the liner instantly (excellent immediate tack) and ensures the liner stays firmly in place through shipping, storage, and countless consumer openings (superior long-term cohesive strength).

2.Built for High-Speed Production

With its fast-curing, non-stringing properties, it perfectly keeps pace with lines producing hundreds or thousands of caps per minute. This reduces downtime, prevents messy adhesive threads from contaminating equipment or caps, and significantly boosts overall output.

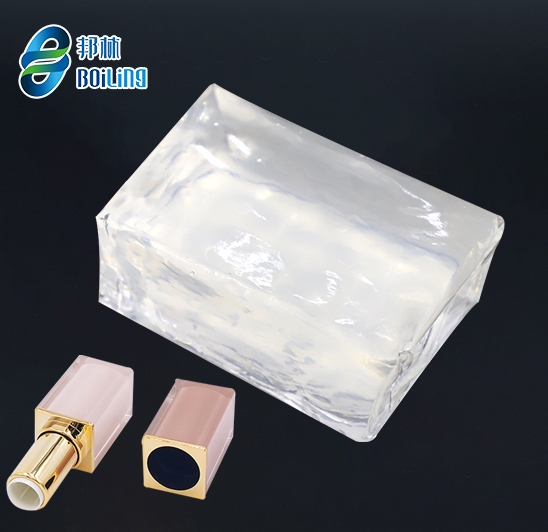

3.Stable & Reliable Temperature Performance

Wines and spirits can face extreme temperature swings, from cold cellars to hot transport trucks. Our adhesive maintains consistent performance across a range of temperatures. Its reliable working range and softening point ensure the seal remains flexible at low temperatures (resisting cracks) and doesn’t over-soften at higher temperatures, guaranteeing integrity throughout the supply chain.

4.Cost-Effective & Eco-Friendly

Our optimized formulation aims to “deliver high bonding performance with relatively low adhesive consumption”, helping you control per-unit costs effectively. The product is also eco-friendly, featuring a solvent-free, low-odor formula that’s safer for both your production environment and the planet.