Hot Melt Adhesive Blocks

We are dedicated to providing customers with comprehensive solutions for hot melt adhesive blocks, covering customized formula development, production process optimization, and continuous application technical support. With stable product quality and an efficient supply chain system, we ensure that each batch of hot melt adhesive blocks meets diverse requirements in terms of bonding strength, temperature resistance, and applicability. At the same time, we attach great importance to after-sales service and collaborative innovation, committed to helping customers enhance product performance and reduce overall costs. We aim to be your reliable technical and supply chain partner in the field of hot melt adhesives, jointly addressing market challenges.

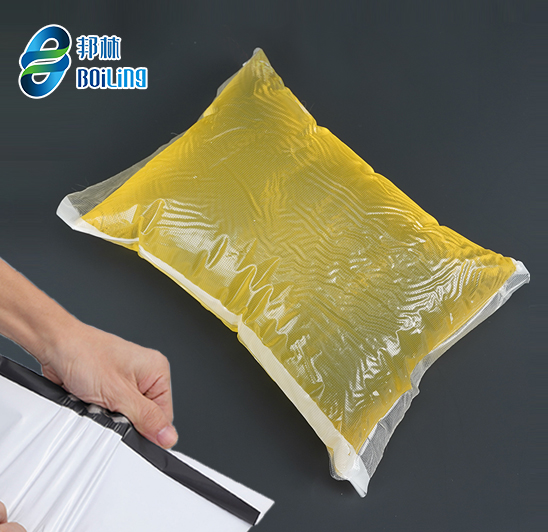

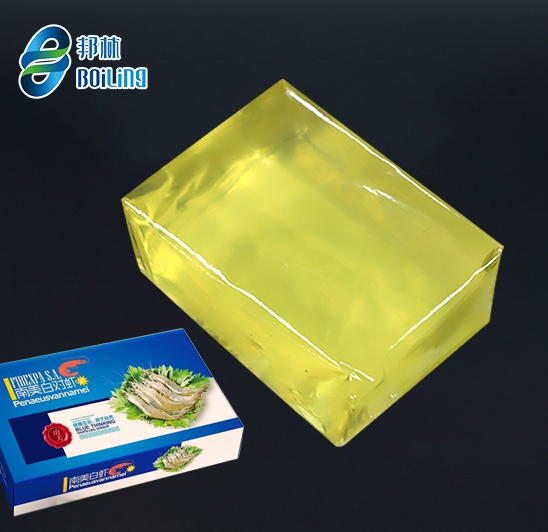

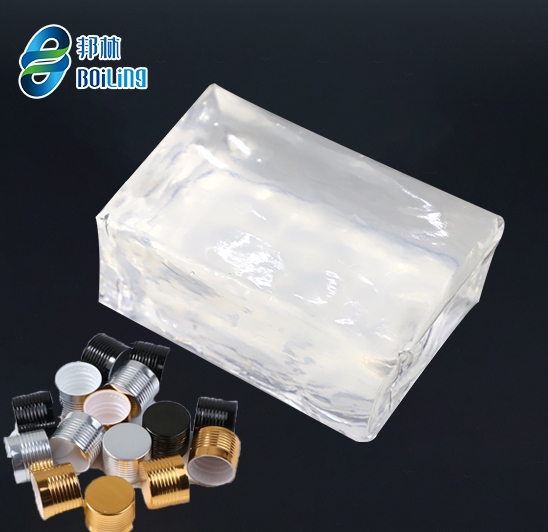

Hot Melt Adhesive Series

Hot Melt Adhesive Solutions

Choosing the right hot melt adhesive is crucial for product quality and production efficiency. Precise matching to the substrate properties and application requirements ensures excellent bond strength, temperature resistance, and process adaptability, avoiding issues like debonding or oozing. A suitable hot melt adhesive not only improves production yield but also extends product lifespan, reducing overall costs. Professional technical support and selection guidance are the core value of achieving an efficient bonding solution.

About Us

Our Hangzhou factory serves more than 3800 customers, covering 23 provinces and 343 cities.lts products are exported to countries such as Southeast Asia and the Middle East. The company has a comprehensive product research and development, quality monitoring,safety production,employee service, and after-sales service management system.The company has successively introduced digital management software such as SAP workshop integration software MES, CRM, cloud barcode and Yida digital platform to assist the enterprise in building a strategic management system.

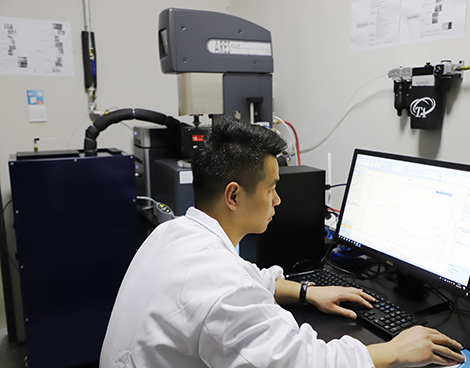

The company has established a technical team with professional application research and development capabilities. The R&D center covers an area of over 500 square meters, importing the most advanced R&D testing instrument- the rheometer from the United States. Meanwhile we also hire experts studied phd in the United States for training and guidance. The company focuses on technological innovation, and continuously enhances the market influence of our independent brand "Boiling", and strives continuously to realize custom elvalue!

Our Trusted Partners

At Boiling Adhesive Technology Co., Ltd, we measure our success by the success of our clients. We are proud to have built lasting relationships with a diverse range of global industry leaders and innovative enterprises. From the demanding precision of the automotive sector to the strict hygiene standards of medical device manufacturing, our adhesive solutions are trusted to deliver unparalleled performance and reliability. These collaborations are more than just business; they are a testament to our shared commitment to excellence and a driving force behind our continuous innovation.