Beyond Paper Achieving Strong Bonds on Challenging Surfaces

Labeling seems straightforward until you hit those tricky containers. Think about a shiny HDPE shampoo bottle rolling off the line, or a clear PET water bottle sitting in a cold fridge case. The label looks great at first. Then comes the nightmare: edges lift, corners flag, or the whole thing slides off in the store. Customers notice. Retailers complain. Returns pile up. For beverage, cosmetics, and household product makers, this isn’t just annoying—it’s expensive.

These problems usually trace back to one thing: the surface. Materials like HDPE, PET, and glass are non-porous and have low surface energy. Regular adhesives struggle to wet out properly. They don’t grab tight. The bond stays weak, especially when condensation forms, temperatures swing, or bottles get squeezed in transit. Industry folks know the drill. On high-speed lines, even a small percentage of loose labels means downtime, rework, and angry calls from buyers.

The fix? A solid label hot melt glue that actually sticks to these tough substrates.

The Real Struggle with Low Surface Energy Materials

HDPE bottles—common for detergents, shampoos, and milk—feel waxy. PET containers, big in beverages, stay slick too. Glass might seem easier, but condensation and smooth surfaces make it just as challenging. Untreated versions of these materials reject most adhesives. The glue beads up instead of spreading. No real contact. No real hold.

Real-world numbers show how bad it gets. In busy bottling plants, label failure rates on untreated HDPE or PET can hit 5-10% during application and early handling. That means thousands of bottles need manual fixes or get scrapped. One mid-sized cosmetics filler reported losing hours each shift chasing flags and peels. Add in transport vibration and cold storage, and failures climb higher. Retail shelves end up with half-attached labels. Brand image suffers. Sales drop.

Pressure-sensitive hot melt adhesives change this picture. They melt quick, apply clean, and form bonds that fight back against those tricky surfaces.

What Makes Label Hot Melt Glue Stand Out

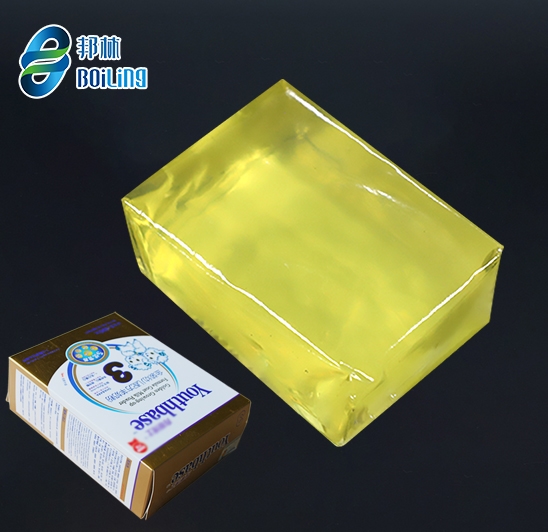

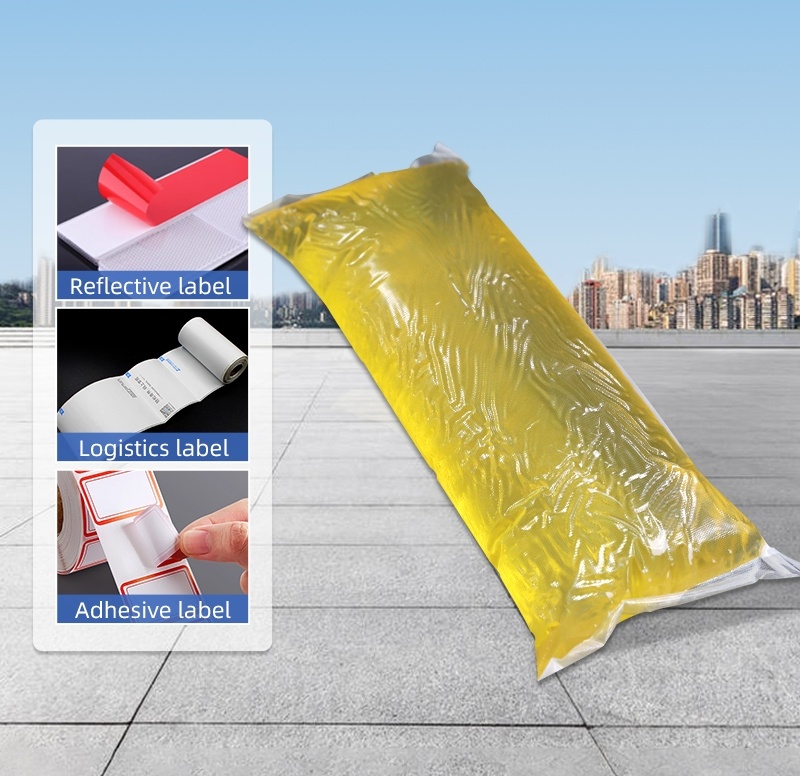

This isn’t basic glue. Label hot melt glue from Banglin is built for the job. It’s pressure-sensitive, synthetic rubber-based, and formulated to grab hard-to-bond materials.

Key things it brings to the table:

- Strong initial tack — grabs the label and container fast on high-speed applicators.

- Excellent wetting — spreads evenly even on low-energy plastics like PP, PE (including HDPE), and PET.

- Long-term hold — resists edge lifting, flagging, and detachment through temperature changes and humidity.

- Good environmental tolerance — handles cold fridges and warm warehouses without losing grip.

Take the specs on their coated paper label hot melt. Yellow blocks, soft point around 95°C, viscosity about 4300 cps at 180°C. Apply it between 150-180°C. It runs smooth on automated lines, no charring or stringing. The bond compares to top pressure-sensitive options, but with the speed and cleanliness of hot melt.

In everyday use, it shines on:

- Beverage bottles (PET water, soda)

- Daily chemical containers (HDPE shampoo, cleaners)

- Food packaging

- Glass jars

Operators love how it keeps lines moving. No frequent stops to clean nozzles. Labels stay put from filler to shelf.

Real-World Wins on Difficult Surfaces

Picture a beverage plant running PET bottles at 400 per minute. Standard glue lets 4-5% of labels flag during the first drop test. Switch to a quality label hot melt glue, and that drops to under 1%. The difference shows up fast: fewer rejects, less waste, happier downstream customers.

Same story with HDPE. Those waxy detergent bottles used to need corona treatment or primers to make adhesives stick. Not anymore. This hot melt wets out directly. No extra steps. No added cost. One household products manufacturer cut labeling defects by over 60% after switching. They saved on rework labor and avoided costly returns from retailers spotting loose labels.

Glass gets love too. Condensation on cold-filled jars kills many bonds. This adhesive holds firm. Labels don’t slide during washdown or storage.

How to Get the Most Out of It

Implementation stays simple if your line already uses hot melt applicators. Melt the blocks, coat the label back, press on the container. Done.

A few pointers from the floor:

- Match application temp to your setup — 150-180°C usually hits the sweet spot.

- Run test batches on your exact containers — slight differences in plastic grade can matter.

- Keep viscosity in check — clean tanks and steady heat prevent issues.

- Monitor line speed — high-speed works great, but watch for even coating.

Dial it in, and the process runs smoother than water-based options. Faster setup. Less mess. Higher throughput.

About Banglin: A Trusted Hot Melt Adhesive Supplier

Banglin, from Hangzhou Boiling Adhesive Technology Co., Ltd., has been delivering reliable hot melt solutions since 2005. As a national high-tech enterprise, they specialize in pressure-sensitive hot melt adhesives for packaging, labels, and more. Their label hot melt glue stands out for strong performance on low surface energy materials like HDPE, PET, and glass. With custom options, consistent quality, and solid support for ODM/OEM, Banglin helps brands solve tough labeling challenges and keep production moving.

Conclusion

Labeling on challenging surfaces doesn’t have to mean constant headaches. By choosing the right label hot melt glue, you get reliable bonds that hold up on HDPE, PET, glass, and other tough materials. You cut down on flags, peels, and rejects. You save time, money, and frustration. Most importantly, your products reach shelves looking sharp and stay that way. In a competitive market, that’s the kind of edge that builds trust and keeps customers coming back.

FAQs

Why does regular adhesive fail so often on HDPE and PET bottles?

These plastics have low surface energy. The glue doesn’t spread well or form a strong bond. It beads up instead of wetting out, leading to weak adhesion that fails with temperature changes or handling.

How does label hot melt glue perform better on low surface energy surfaces?

It’s specially formulated to wet out and grab tricky materials like HDPE, PET, and PP. It delivers strong initial tack and lasting peel strength, keeping labels flat and secure without lifting or flagging.

Can label hot melt glue handle condensation on cold glass or PET bottles?

Yes. It maintains good adhesion even with moisture and temperature swings. Labels stay put through fridge storage, transport, and shelf time without sliding or peeling.

Is label hot melt glue suitable for high-speed labeling lines?

Definitely. It melts cleanly, coats evenly, and sets fast. It works great on automated equipment, helping plants run faster with fewer stops and defects.

What types of labels and containers work best with label hot melt glue?

It excels on coated paper, thermal paper, and plastic film labels. It bonds reliably to PET beverage bottles, HDPE household containers, glass jars, and other common packaging surfaces.