How to Solve Production Bottlenecks in High-Speed Wine Bottle Capping Lines with Hot Melt Technology

Running a high-speed express bag sealing line means every second counts. One weak bond or a nozzle clogged with stringy glue can stop the whole operation, pile up rejects, and eat into profits fast. The right hot melt adhesive isn’t just “good enough”—it’s the difference between smooth output and constant headaches.

Most express bag producers—think courier companies, e-commerce fulfillment centers, and third-party logistics packers—need glue that can keep up with machines hitting 80–150 bags per minute. That’s where picking the correct express bag hot melt glue becomes critical. You’re not just buying a sticky substance; you’re choosing a material that has to perform under pressure, heat up quickly, set fast, and stay reliable through cold storage or hot summer warehouses.

Let’s walk through the key things to look for so your line runs without drama.

Viscosity: Getting the Flow Just Right

Viscosity controls how the glue behaves the moment it leaves the nozzle.

- Too thin(low viscosity) → glue splatters, creates messy dots, and often bleeds through thin kraft paper.

- Too thick(high viscosity) → poor wetting on coated surfaces, weak bonds, and frequent nozzle clogs.

For modern high-speed express bag lines,medium to fairly thick glues work nicely. Think roughly 1,500 to 4,000 cps at running temp. They lay down a neat bead. It sits cleanly on the flap. No running. Yet it still wets both plain kraft and coated papers enough to grab hold.

Real-world example: One mid-sized courier packaging plant switched from a very low-viscosity glue to a slightly thicker formulation. Stringing dropped by about 70%, and they cut cleaning stops from three times per shift to once every two days.

Initial Tack: How Fast Does It Grab?

Tack is that “grabby” feeling you get the instant the glue touches the second surface.

In high-speed sealing, you need aggressive initial tack because the compression time is extremely short—sometimes under half a second. If the glue doesn’t grab quickly, flaps pop open later in transit or during automatic sorting.

Look for products that combine fast initial grab with a reasonable open time (the window before the glue skins over). Many manufacturers test this on actual kraft and coated express bag stock at line speeds. Ask for samples and run them on your own equipment—lab numbers look nice, but real machine behavior is what matters.

Temperature Range: Surviving the Real World

Express bags travel everywhere—from freezing winter trucks to hot shipping containers in summer.

A good express bag hot melt glue should hold strong from about -20°C to 60°C after full cure. But the application temperature matters just as much. Most high-speed lines run glue pots between 140–170°C. Adhesives that stay stable at these temperatures (without charring, smoking, or degrading) last longer in the tank and cause fewer maintenance issues.

Quick tip: If your line has frequent temperature swings or long idle periods, pick a glue with a wider processing window. It forgives small operator errors and keeps performance consistent across shifts.

Low Stringing: The Silent Killer of Clean Lines

Nothing annoys operators more than spider-web strings trailing from the nozzle.

Stringing happens when the glue has too much elasticity as it cools. High-speed lines make it worse because the nozzle moves quickly and the cutoff isn’t always perfect.

Look for adhesives that advertise low-stringing or “clean cutoff” properties. In practice, these formulas usually have carefully balanced polymer content and additives that reduce melt elasticity without killing tack or bond strength.

From the field: Plants that switched to low-stringing formulations report 30–50% less glue residue on the applicator heads and noticeably cleaner conveyor belts downstream.

Open Time vs. Set Time: Finding the Sweet Spot

- Open time— how long the glue stays liquid and bondable after application.

- Set time— how fast it solidifies under compression.

For high-speed express bag sealing, you usually want:

- Open time: 3–10 seconds

- Set time: 1–4 seconds

Too short an open time → glue skins over before the flap closes. Too long → bags stay “wet” and can shift or pop open during stacking.

Most successful lines run adhesives with a fast set time (under 3 seconds) and just enough open time to handle slight variations in flap alignment.

Other Practical Factors That Matter

Here are a few more things experienced packaging managers always check:

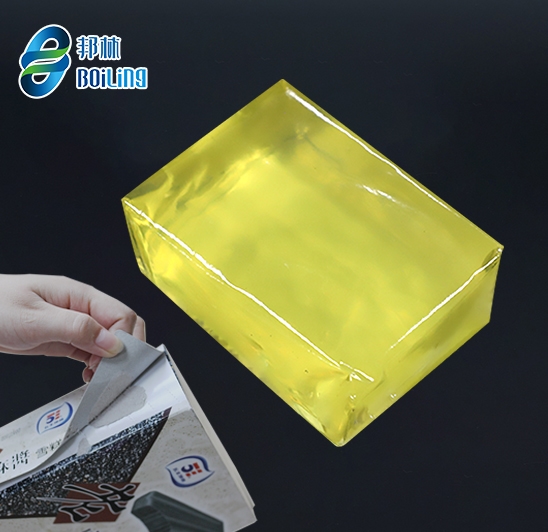

- Color and odor— light amber or almost clear glues look cleaner on white or printed bags. Low-odor formulas keep the work environment more comfortable.

- Thermal stability— glue that doesn’t gel or char after sitting at temperature for hours.

- Substrate compatibility— good wetting on both recycled kraft and glossy coated papers.

- Food-contact status— even though most express bags aren’t food-related, many plants prefer adhesives that meet indirect food-contact standards for flexibility.

- Cost per bond— not just price per kilo. Calculate grams used per bag × cost per kilo to get the true running cost.

Comparison of Key Performance Needs

|

Property |

Low-Speed / Manual Lines |

High-Speed Automated Lines |

Why It Matters on High-Speed |

|

Viscosity |

500–2,000 cps |

1,500–4,500 cps |

Clean bead, no splatter |

|

Initial Tack |

Moderate |

High / Aggressive |

Instant grab needed |

|

Set Time |

5–15 seconds |

1–4 seconds |

Fast handling & stacking |

|

Stringing |

Tolerable |

Very low / Clean cutoff |

Less cleaning downtime |

|

Temperature Stability |

Basic |

Excellent |

Long pot life, less char |

|

Operating Temp Range |

130–160°C |

140–175°C |

Matches modern applicators |

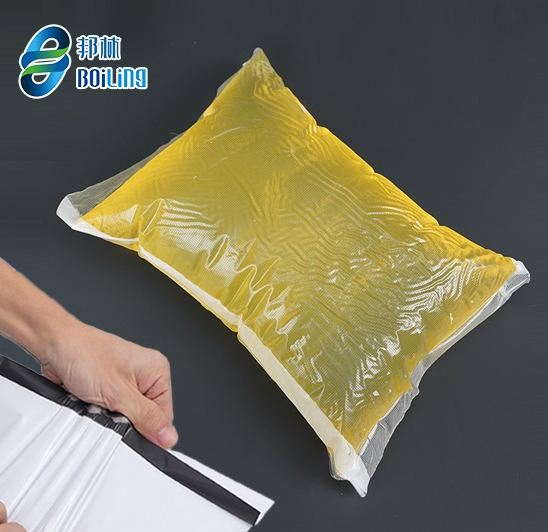

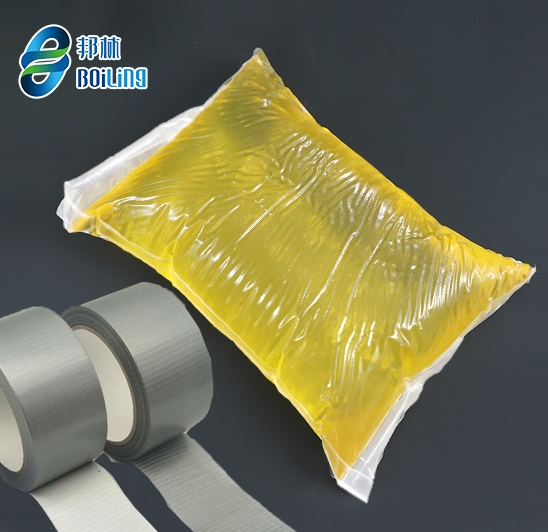

Banglin – A Trusted Hot-Melt Adhesive Products Supplier

Banglin (Hangzhou Boiling Adhesive Technology Co., Ltd.) has been developing and manufacturing hot melt adhesives since 2005. They specialize in pressure-sensitive hot melt solutions, including dedicated express bag hot melt glue designed for high-speed packaging lines. With a strong focus on customization, stable quality, and technical support, Banglin works closely with packaging manufacturers to match adhesive performance to real production conditions—whether it’s fast-setting needs, low-stringing behavior, or wide temperature tolerance. Their products aim to deliver reliable bonding while keeping long-term running costs under control.

Conclusion

Choosing the right express bag hot melt glue isn’t about finding the “strongest” glue on paper. It’s about matching the adhesive to your actual machine speed, substrate type, environmental conditions, and quality targets. A formulation that runs beautifully at 60 bags per minute might fail completely at 120. Viscosity, tack, stringing behavior, and set time need to work together—not just look good on a spec sheet.

Take the time to test samples on your own line. Talk openly with your supplier about your real pain points—downtime, rejects, cleaning frequency, or bond failures in cold weather. The best adhesive decisions usually come from that kind of honest conversation and hands-on trial.

When you get it right, the line runs smoother, operators stay happier, and those late-night emergency glue changes become a thing of the past.

FAQs

Q1: What’s the best viscosity range for express bag hot melt glue on high-speed lines?

Most high-speed packaging lines perform best with express bag hot melt glue in the 1,500–4,500 cps range (measured at application temperature). This gives a clean bead without excessive stringing or bleeding through the paper.

Q2: How can I reduce stringing when sealing express bags?

Choose a low-stringing formula specifically designed for high-speed cutoff. These glues have adjusted elasticity and usually show much cleaner breaks at the nozzle. Also make sure your applicator temperature stays in the recommended range—too hot often makes stringing worse.

Q3: Does temperature resistance really matter for courier bags?

Yes. Bags can sit in -15°C trucks overnight and then bake in 50°C+ sorting facilities. A good express bag hot melt glue should maintain bond integrity across -20°C to 60°C to avoid flap pop-open complaints during delivery.

Q4: How do I know if the glue is compatible with coated express bag paper?

Run a simple wetting test with a sample. The glue should spread evenly and form a strong bond without beading up or delaminating after 24 hours. Ask your supplier for formulations already proven on coated and recycled kraft stocks.

Q5: Can I switch glues without major line adjustments?

Usually yes—if you stay within a similar application temperature and viscosity range. Still, always do a small trial run first. Even small changes in set time or tack can affect timing on very fast lines.