The Ultimate Guide to Choosing a Hot Melt Tape Adhesive for Heavy-Duty Packaging

Heavy-duty packaging puts tapes through tough tests. Rough handling. Big temperature changes. Long trips. One weak spot—the adhesive—can let packages split open. That means ruined goods, late deliveries, and higher costs. For folks who make tapes, picking the best hot melt tape adhesive turns the difference between solid performance and endless customer gripes.

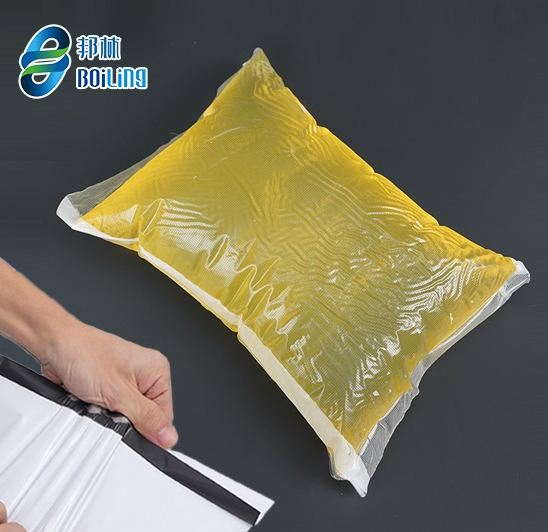

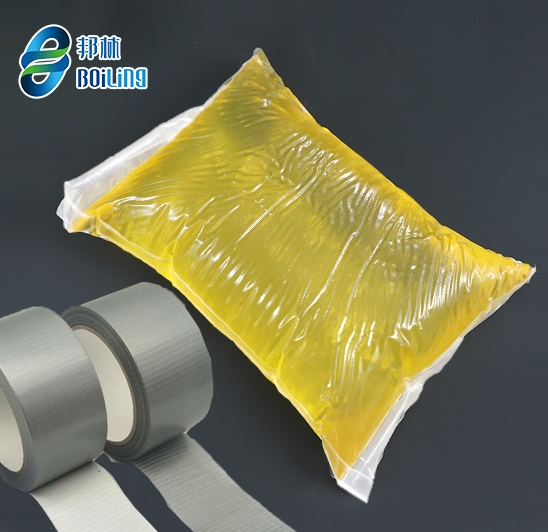

Cloth tape adhesive really shines in these tough jobs. It sticks well to woven backings. That creates strong, bendy tapes. Perfect for tying up heavy loads, closing big boxes, or quick fixes in plants and warehouses. This guide covers what really counts when you select hot melt tape adhesive for demanding uses. We keep the focus on actual needs from tape production floors and how tapes hold up in real life.

What Is Hot Melt Tape Adhesive and How Does It Work?

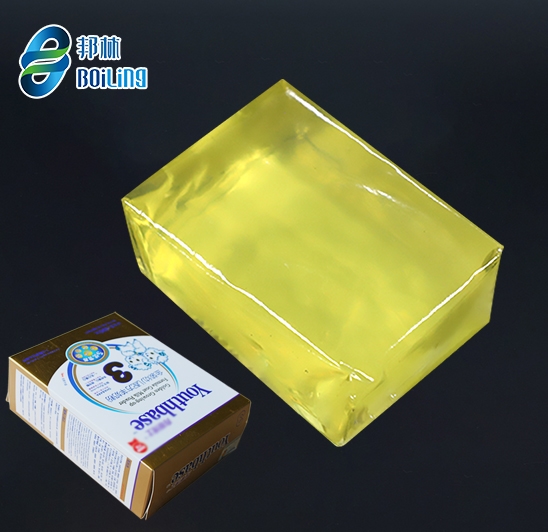

Hot melt tape adhesive falls into the pressure-sensitive hot melt group, usually called HMPSA. You warm it until it flows easy. Then coat it onto cloth, paper, or film backings. After it cools, the surface stays sticky. Press it down, and it grabs right away. No solvents. No waiting around for it to dry.

This method speeds things up a lot on the line. Coating runs quicker since the adhesive hardens fast once cooled. For cloth tape adhesive in particular, the mix has to sink just right into the fabric weave. It needs solid hold there. At the same time, it leaves plenty of tack on top for instant bonding later.

Compared with old solvent types, hot melt tape adhesive cuts way down on fumes. Cleanup gets simpler too. Lots of these formulas store well and fight off aging. Tape makers get steady rolls, batch after batch, for months on end.

Why Cloth Tape Adhesive Excels in Heavy-Duty Packaging

Cloth tapes stand out when strength and flexibility matter most. The woven cotton or polyester base resists tearing. It bends better than plain paper tapes. When you pair it with good cloth tape adhesive, the tape handles bumps, odd shapes, and some outdoor time.

Picture a shipping crew wrapping heavy machine parts on pallets. The tape has to grip rough cardboard or stretch film tight. It fights shear from shifting loads. It stays put even when heat builds up inside a trailer. Cloth tape adhesive brings the high shear and quick initial grab that keep everything locked down. No peeling. No messy residue.

In construction crews or HVAC jobs, people grab cloth tapes to seal ducts or bundle pipes. The adhesive needs to stand up to heat without going soft in summer. It can’t turn brittle in cold spots either. A solid cloth tape adhesive holds the bond steady across big temperature swings—often from freezing up to 60°C or more, depending on the grade.

Production lines feel the benefit too. When the adhesive spreads even and clean—no strings, no webs—downtime shrinks. Quality stays high. Tape makers see fewer bad rolls and smoother runs once the hot melt tape adhesive fits their backing and machines just right.

Key Properties to Evaluate When Selecting Hot Melt Tape Adhesive

Tape producers need to look at several key traits before locking in a new adhesive. Think about how each one affects your coating setup and how the finished tape behaves out in the field.

- Initial Tack: Shows how fast the tape sticks on touch. High tack helps quick hand or machine application in busy packing areas. Pick formulas that grab strong yet avoid too much leftover goo.

- Peel Adhesion: The pull needed to yank tape off stuff like cardboard or steel. Heavy-duty jobs want strong peel that stops edges from lifting under heavy weight.

- Shear Strength: Vital for fighting slide on upright or loaded packages. Solid shear stops creep even when pressure lasts a long time.

- Temperature Resistance: Covers coating heat (usually 150–180°C) plus service range. Warehouses get hot. Trucks get cold. The adhesive should avoid softening or cracking in those spots.

- Viscosity and Flow: Controls smooth spreading at line speeds. Too thick means patchy coats. Too runny and it soaks deep into cloth, stiffening the tape.

- Aging and Environmental Resistance: Fights UV, damp air, and breakdown over time. That keeps tack and strength steady on shelves and in use.

Here’s a quick reference table of what matters most for heavy-duty packaging:

|

Property |

Why It Matters |

What Tape Manufacturers Should Prioritize |

|

Initial Tack |

Fast application on irregular surfaces |

Strong grab without stringing |

|

Peel Adhesion |

Secure hold on cardboard, plastic, metal |

High values on multiple substrates |

|

Shear Strength |

Holds heavy loads without sliding |

Excellent cohesion under stress |

|

Temperature Range |

Survives hot warehouses or cold shipping |

Wide service window without failure |

|

Flexibility |

Conforms to curved or rough items |

Good on cloth backings without cracking |

Run your own lab checks or pilot coats. Small test rolls show problems fast—like edges lifting or weak fiber grip—before you go big.

Production and Application Factors for Tape Manufacturers

Your coating equipment sets real boundaries. Hot melt tape adhesive has to run clean at your normal speeds and temps. No constant nozzle wipes or web snaps. Cloth soaks up more than films do. So choose mixes that limit soak-in. Enough for grip, but not so much the tape gets stiff or shows bleed.

End users in heavy-duty packaging run into dust, moisture, or light oils often. A forgiving cloth tape adhesive handles small surface dirt better than picky grades. Storage plays a part too. Some hot melt types keep tack longer even in steamy weather.

You can tweak things. Change open time, shade, or block size to match gear or branding. Shorter open time fits fast auto applicators. Longer open time gives hand packers room to line things up right.

Watch out for traps. Great lab stats mean nothing if the stuff runs badly on your line. Or if humidity kills tack over weeks. Smart operators coat full batches and mimic real stress—drops, heat-cold cycles, heavy holds—before ramping up.

Introducing Banglin as a Hot-Melt Adhesive Products Supplier

Banglin (Hangzhou Boiling Adhesive Technology Co., Ltd.) started back in 2005 in Hangzhou Future Science Industrial Park. They focus on hot-melt adhesive products as a national high-tech outfit. Their R&D setup includes serious gear like imported rheometers for deep viscoelastic checks.

Banglin specializes in pressure-sensitive hot melt adhesives. That covers dedicated hot melt tape adhesive and cloth-based tape hot melt adhesive options. Their lineup hits cloth tape, kraft paper tape, PET, foam, aluminum foil, and more. They team up directly with tape makers through ODM and OEM work. Custom formulas tackle specific bonding headaches, line settings, and performance goals.

Mature processes, full batch tracking, and choices for custom colors or packs (blocks under 1 kg up to big cartons or pallets) make scaling easy. Orders kick off at 2000 kg minimum. One-on-one tech help lets clients fine-tune adhesive behavior for heavy-duty packaging tapes. No need to build your own lab from zero.

Conclusion

Picking the right hot melt tape adhesive for heavy-duty packaging goes way beyond simple stick. You balance grab, strength, heat handling, and easy running. That way your cloth tapes work dependably—from the coating step straight through to the warehouse floor. Pay attention to actual use demands. Test hard. Team up with suppliers who get tape-making details.

When the adhesive just does its job quietly and every time, your tapes build a name for toughness. Fewer returns come in. Customers stick around longer. Your business grows smoother. Spend time matching properties to your exact setup. The rewards show up roll after roll.

FAQs

What is hot melt tape adhesive, and why do tape manufacturers use it for cloth tape production?

Hot melt tape adhesive is a thermoplastic pressure-sensitive type. You apply it hot, then cool it to form a tacky coat on the backing. For cloth tape adhesive, it sinks partly into the weave for firm hold while keeping the top sticky. Tape makers go for it because lines move fast. Cleanup stays simple. Finished tape bonds quick under pressure—great for cranking out durable rolls in volume.

How does cloth tape adhesive perform differently in heavy-duty packaging compared to other tape adhesives?

Cloth tape adhesive gets made for bend and high shear on rough, porous faces. It wraps around odd shapes like pipes or pallet corners without splitting. Its hold fights heavy or shaky loads better than many film or paper options. In heavy-duty packaging, that cuts down on breaks during bumpy rides or storage where temps jump around.

What key factors should I consider when choosing hot melt tape adhesive for my tape line?

Look at initial tack for fast stick, peel and shear for carrying weight, temperature hold for your storage and transit spots, plus viscosity for clean coats on cloth. Run small tests to check no strings, good fiber grab, and steady results after sitting. Fitting these to your machines and markets stops expensive tweaks down the road.

Can hot melt tape adhesive be customized for specific heavy-duty packaging needs?

Sure thing. Suppliers tweak open time, tack strength, color, and heat resistance to suit your line speed, local weather, or buyer specs. For cloth tape adhesive, small changes boost grip on polyester versus cotton or improve hold in muggy air. That lets tape makers stand out without swapping big equipment.

Is hot melt tape adhesive a good environmental choice for tape production?

Most current hot melt tape adhesive mixes skip solvents and meet low-VOC rules. They help keep plants cleaner and fit many packaging standards. When you source from solid producers, the final tape often recycles easier than solvent-based kinds too.